So...big day in gear box land...and it went a little something like this...

Woke up, thought of K and decided at once to chuck a sickie

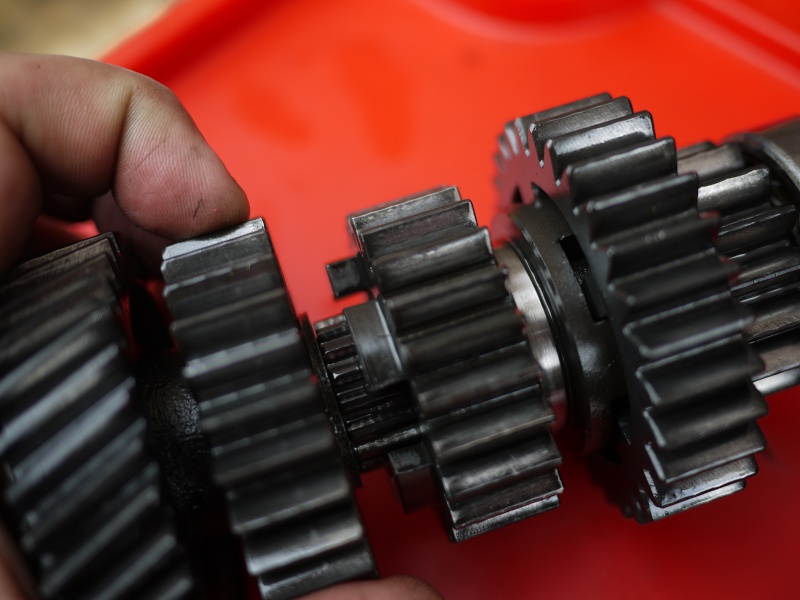

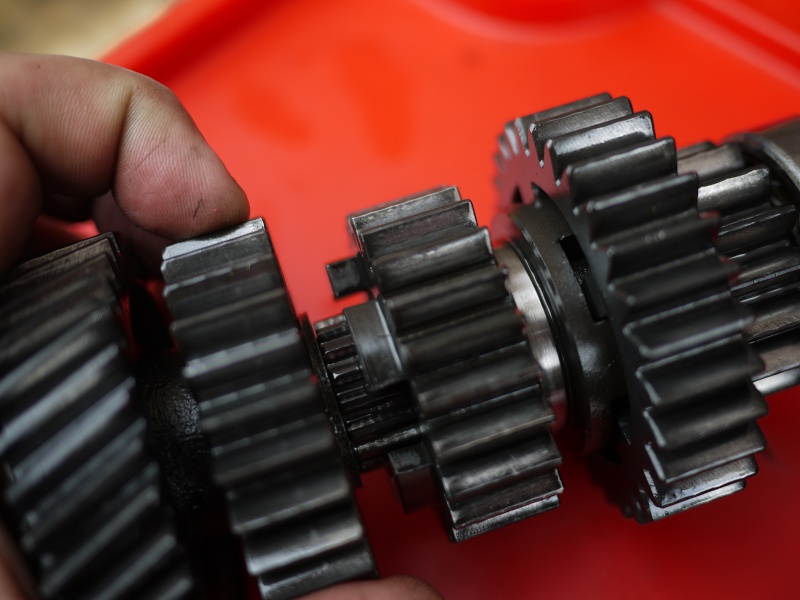

Opened another K100 gearbox I have here and removed the shafts. After cleaning them up a bit I did a pretty thorough inspection.

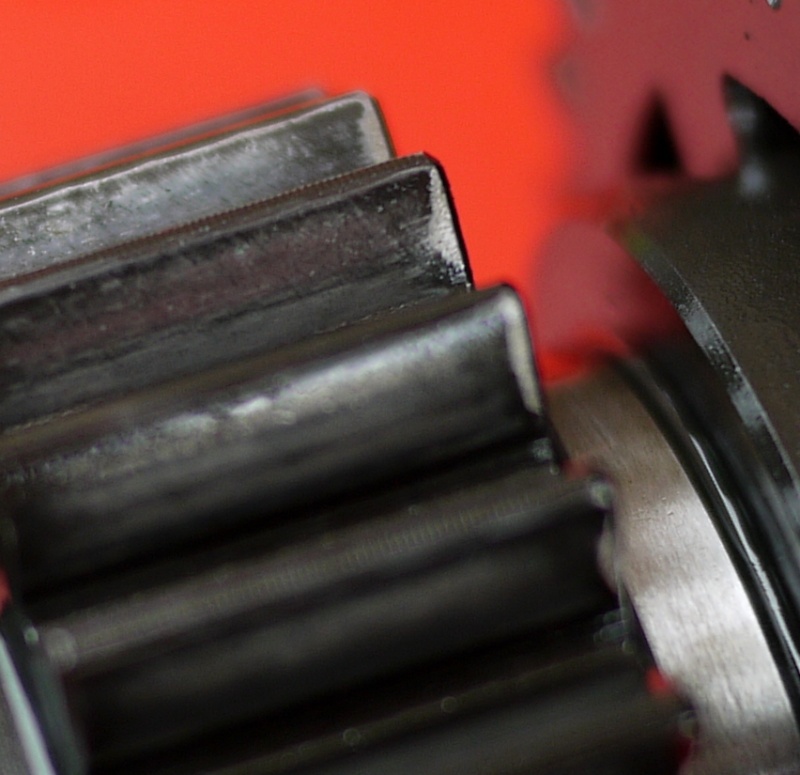

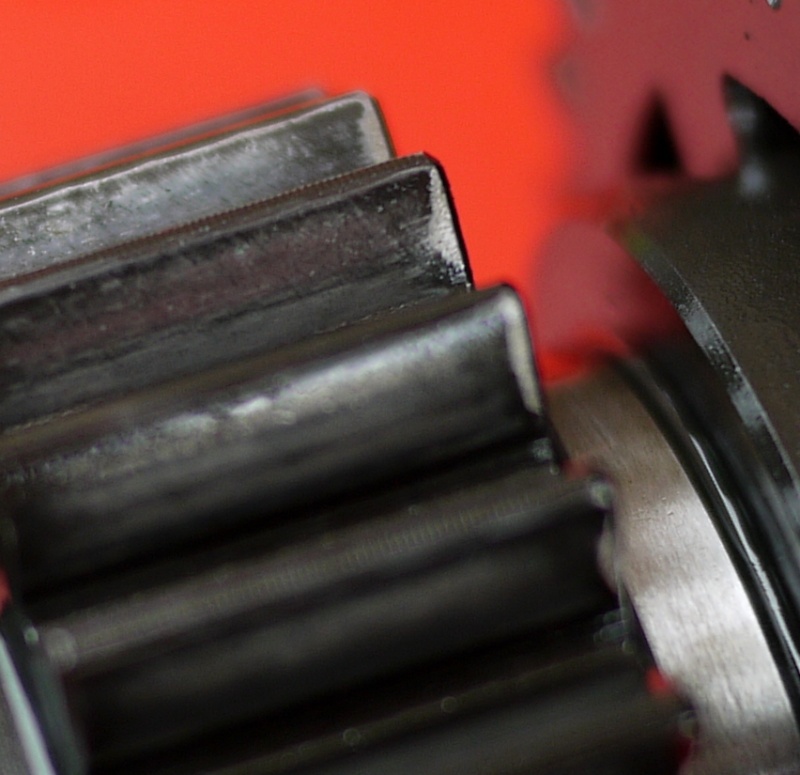

It looked pretty nice I have to say, nice enough to make me go and re inspect the ones out of the main gearbox Im working on. One the original 84RS gearbox that I was planning to use, I noticed a bit of wear on one of the gears and a little bit less wear on its matching gear. This is wear and abrasion that is not present on the shafts from the other box, so I made an executive decision to use the Output/Intermediate shaft from the 2nd gearbox, and the Input shaft (and everything else) from the 1st gearbox.

Id then realised that I had been a bit pre-emptive on the fitting of the GPI seal and the gear lever seal, as I needed to heat the entire case in the oven to permit the removal of a bearing race inside the case. Bugger, 2 seals wasted....

I started re-stripping the gearbox case just as the postie arrived with my nice (cheap) new bearing puller set. Off to work pulling bearings off shafts then! After some initial fiddling, the bearings were popping right off, sweet as.

All the new bearings went on without a hitch, except the one on the output shaft at the end with the splines. I didnt have a socket or bar wide and deep enough for the job. No worries! Off to the local mechanic who has helped me several times now with such things

I then popped the main gearbox case in the oven on a fairly low heat (to low in fact) and wait an hour or so, took it out side, banged the crap out of it on a wooden block - all to no avail. The bugger wouldnt move.

The race in the cover plate is able to be carefully knocked out with a punch, and this is what I did - but alas, the one in the case is not.....

I decided to put it back in the oven at about 200c for about 45 mins. Took it outside, banged it once, and jingaling, out pops the race, in goes the new one, piece of cake.

Soooo, all the new bearings are on, except the last one on the input shaft - need to do some measurements first. The Intermediate and output shafts are in their new homes. Just need to do the preload and endfloat measurements etc and finish the assembly and reconditioned gearbox, hear we come.

Re: Around the World On a K100 Wed Apr 02, 2014 1:26 am

Re: Around the World On a K100 Wed Apr 02, 2014 1:26 am

Ich bin enge Kirchröatsjer jong; adieë wa ?!

Ich bin enge Kirchröatsjer jong; adieë wa ?!