1

Instrument cluster bulb fittings Sat Aug 07, 2021 8:23 am

Instrument cluster bulb fittings Sat Aug 07, 2021 8:23 am

tinyspuds

Life time member

Dai wrote in response to a charging light issue I have:

……….

2. One or both copper tabs on the flexi-pcb has folder backwards rather than be poking down into the bulbholder's socket. It's dead easy to miss this when putting the bulbholder back in. What happens is

- you pull the bulbholder out and as you do so, the flexi-pcb flexes far enough so that the copper tab(s) clear the socket

- the copper tab(s) move into a position that is just slightly more than 90 degrees to the socket

- the flexi-pcb snaps back down but the copper tabs don't go back into the socket - that over-angle causes them to fold under the main flexi-pcb

- there's still enough copper exposed to make a connection with the bulbholder's contacts (most of the time)

- eventually they either stop making contact or they fracture away from the main flexi-pcb.

Seen a few like that. Actually, seen a lot like that.

—————————————————————————————————-

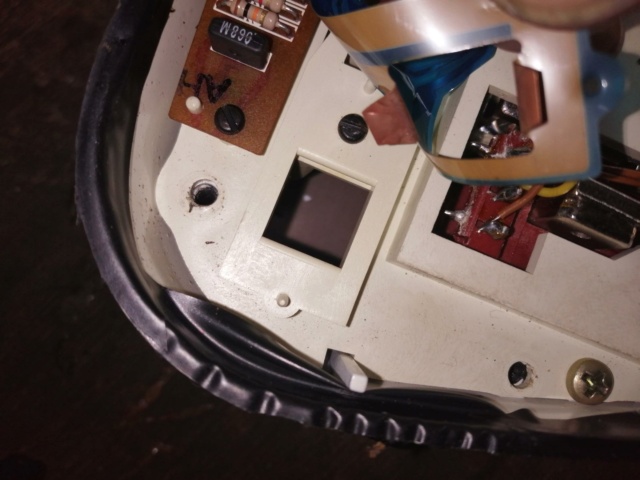

As I have the cluster open I thought photos for those unfamiliar (like I was 10 minutes ago) might be helpful.

Circled yellow is one of the backlight bulb fittings.

Circled red is an empty socket with the copper tabs lifted away from the socket sides when the bulb fitting was removed.

This is a backlight bulb and socket. The bulb is pushfit in either orientation (unless you have LEDs in which case orientation matters.

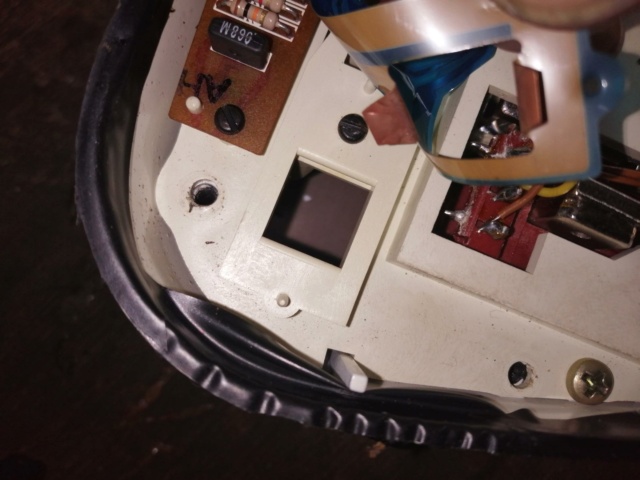

Underside of the flexi strip with the copper tabs for a backlight. Easy to see how these might fold under the strip rather than descend into the socket.

……….

2. One or both copper tabs on the flexi-pcb has folder backwards rather than be poking down into the bulbholder's socket. It's dead easy to miss this when putting the bulbholder back in. What happens is

- you pull the bulbholder out and as you do so, the flexi-pcb flexes far enough so that the copper tab(s) clear the socket

- the copper tab(s) move into a position that is just slightly more than 90 degrees to the socket

- the flexi-pcb snaps back down but the copper tabs don't go back into the socket - that over-angle causes them to fold under the main flexi-pcb

- there's still enough copper exposed to make a connection with the bulbholder's contacts (most of the time)

- eventually they either stop making contact or they fracture away from the main flexi-pcb.

Seen a few like that. Actually, seen a lot like that.

—————————————————————————————————-

As I have the cluster open I thought photos for those unfamiliar (like I was 10 minutes ago) might be helpful.

Circled yellow is one of the backlight bulb fittings.

Circled red is an empty socket with the copper tabs lifted away from the socket sides when the bulb fitting was removed.

This is a backlight bulb and socket. The bulb is pushfit in either orientation (unless you have LEDs in which case orientation matters.

Underside of the flexi strip with the copper tabs for a backlight. Easy to see how these might fold under the strip rather than descend into the socket.

__________________________________________________

1985 BMW K100RT + Hedingham HUB and LL’s. VIN 0028106.

1986 K100RS in boxes. VIN 0141918.

1954 Royal Enfield 350 Bullet. Original.

2000 Hayabusa with Charnwood chair, Wasp forks and EZS wheels.

K1100RS/LT - R1200RT - R1100RS - Cagiva SST 350 Ala Verde - K75LT project - K75 Schurgers - K75S - K1100RS - K75RT - K75C

K1100RS/LT - R1200RT - R1100RS - Cagiva SST 350 Ala Verde - K75LT project - K75 Schurgers - K75S - K1100RS - K75RT - K75C