51

output shaft queries Tue Feb 18, 2020 7:45 am

output shaft queries Tue Feb 18, 2020 7:45 am

audibob

Life time member

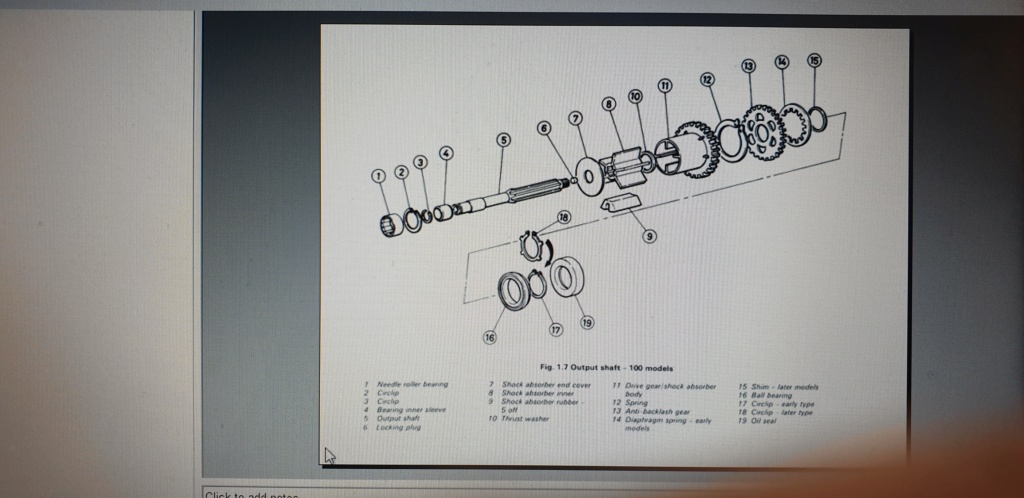

onto the ouptput shaft splines.

BMW only supply two washers anyway, I think the 1.25 is to allow the seal to sit

on an unused part of the shaft. I left my seal protruding slightly with the 1mm washer, you get the same result

either way.

My damper housing does not contact the gear housing when fully pushed together, so the need for

a thrust washer is confusing. BMW do not show one, but everybody else does.

BMW states that, if there is excessive engine noise, file away part of the annular spring tang, or in my case,

one of the spring pin holes, to reduce the tension, and therefore increase free play between the gear sets.

So...you make thousands of these engines, BUT you may need to strip the bugger down and attack

it with a file to make it quiet.

Engineering ...really.

Of course, in order to do this , you need to check it before removing the upper sump casting,

and even then, you only get a small view of it behind the crank.

Things can only get better , or quieter.

I have ordered some moly spray for the gear sets, so in about a week, when swmbo stops giving

me other jobs, I can start assembling the gearsets and check the movement of the backlash gear

and spring.

Then I will refit the shaft in position, supported by cargo straps, and attempt to check the gear free play as per

the bulletin. Fingers crossed I can keep the file in the toolbox.

Finally...

The output shaft needle bearing outer casing has an oilway , given that there is no oil gallery feed from the

bearing upper housing, I presume to fit the bearing with the oil hole at the bottom, for splash feed ??

Bob