yippee ...!

nice and sunny here at last after weeks and weeks of rain ....quite unseasonal

so gave gerty a wash

also have been cleaning up an afm

taking all the lumps bumps etc out of the air path

on completion I thought I would do some measurements to confirm the mechanism and electronics is working well

...most of the readings were good ...

that is

the air temp sensor measured in range

the multi resistor cascade across the potentiometer was also good

BUT I found some inconsistencies from the wiper of the potentiometer which follows the vane on the afm

here's what I found

according to the table in the electronic trouble shooting guide

most of my measurements fell into spec ....or there about allowing for percentage errors

pin 7-5 measured 95.2

pin 7-8 measured 352

pin 8-5 measured 360

pin 8-9 measured 203.6 at about 15 deg c going lower if you breath on it

pins 7-5 actually measure the wiper off the pot assembly

I thought to open the vane and test the movement

along its track it was going weirdly very high in resistance for only a millisecond or so and seemed to be related to change in movement

at near full open ...I think I got something like 900 ohms but it changes at it hits the end sector to about 400 something ohms

plus I couldn't get it to read the same consistent value as the vane was closed

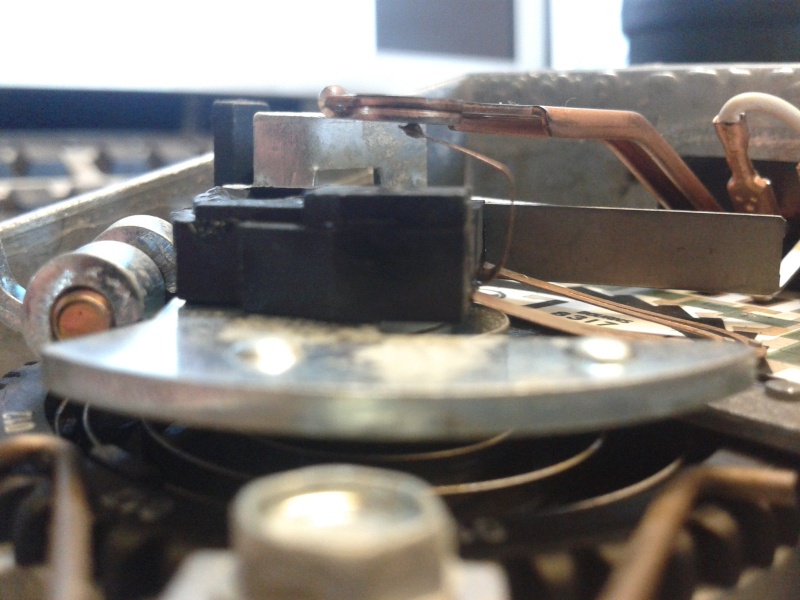

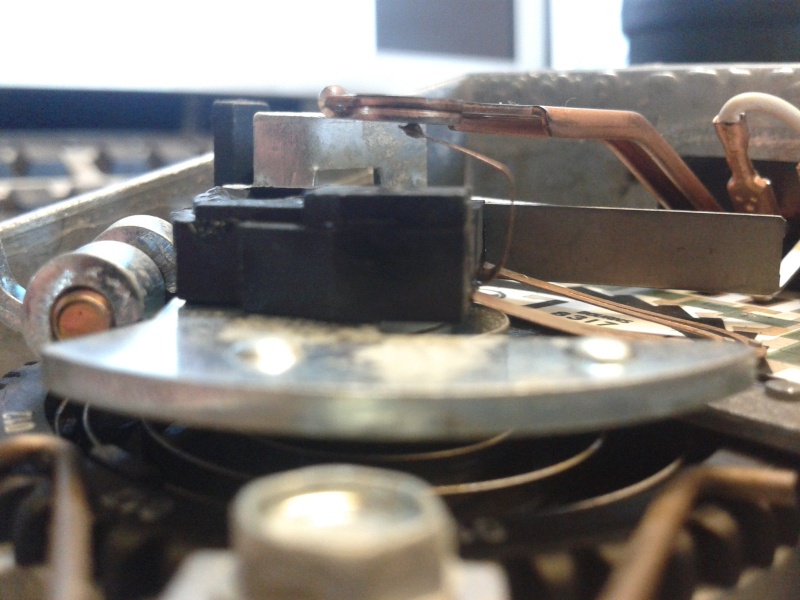

so I had a bit of a look inside

there is a pivot pin and anvil type arrangement to make contact of the wiper to the output on pin 7

I found this contact to be faulty

or more importantly intermittent along its range of movement

carefully I got some really fine 1500 grade wet and dry and cleaned up both the pin contact and the anvil plate ...so that when measured directly across the junction the reading was a stable short circuit in all positions ....and whilst it was vibrated

later I cleaned the surfaces with deoxit gold

I also cleaned up the carbon track of the wiper ...and just to be sure, released the positioning screws that hold the assembly in relation to the vane mechanics .

this was to get a new region of carbon for the wiper to wipe across .

after relocation I locked up the screws and sealed them with nail polish ...which should hold forever

and also marked the position of the spring load position for future reference

this unit had been opened before ...and I suspect had been declared faulty and consigned to the rubbish bin

or else it must have been giving pretty weird mixtures during operation

with this work done ...I can now close the vane and achieve a reading within a couple of ohms (near 100 ) every single time

just thought I should share this for others with the 8 valve motor fitted with jettronic and afm

could save someone a packet

some of the work I did to the edges and bumps through the body of the afm

before

Re: 85 rt resto ...my attempt ...hey im not into making a show bike ... Sat Jun 08, 2013 7:54 pm

Re: 85 rt resto ...my attempt ...hey im not into making a show bike ... Sat Jun 08, 2013 7:54 pm

before

before