1

Replace K100 AFM by a MAF Mon Sep 26, 2022 8:05 am

Replace K100 AFM by a MAF Mon Sep 26, 2022 8:05 am

jcd06

active member

The idea started in Beamers excellent thread about Bosch air flow meter restoration

https://www.k100-forum.com/t11055-bosch-air-flow-meter-restoration-summary

but it is better to make a separate thread for it.

Using MAF on the K100 has been tried before but I couldn’t find any working (and driving) example.

Let us know if you do.

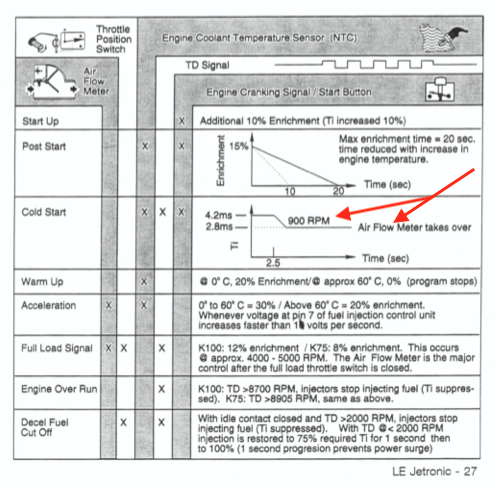

The K100 uses a vane-type airflow meter (AFM).

Mass airflow meters (MAF) didn’t exist in the early eighties or were expensive or unreliable I don’t know.

First MAF versions used a thin heated wire and can I imagine they were somewhat fragile.

Present-day MAF use a hot film and that looks much more robust.

Nowadays MAF are common, inexpensive and reliable, and they offer an attractive alternative to the AFM.

Prices vary from roughly 25 to 150€.

Compared to AFM, they cause less restriction of the airflow, they are less bulky and they are available on the market, while the original AFM is available as second hand item only.

Disadvantages of the use of a MAF. The measuring element can accumulate dirt from a poor air filter or oil from an over-oiled cotton gauze filters (K&N and co), causing erroneous measurements.

There is a major challenge in using a MAF instead of AFM. They have a different output signal versus airflow and thus require another ECU or a signal converter.

Aftermarket ECU is rather expensive and absolutely not plug-and-play.

It’s the signal converter way I would like to explore. It’s less invasive compared to the ECU path.

Is it worth ditching the AFM in favour of a MAF?

Depends what you want. If you’re happy with your bike and you don’t like experiments than don’t go for it. As such, the K100 was and still is a very good design.

For me it’s a technical challenge and I love that.

As the MAF will cause less resistance to airflow it should in principle yield some extra power, although I don’t expect to gain more than a leg of a horse.

So one will need a signal converter to modify the MAF output signal to the AFM input of the ECU.

There are probably more but I found two companies offering this as a finished product

http://max.pilotpowersupply.com/product/pilot-vaf-to-maf-converter-with-a-bluetooth-interface/

https://splitsec.com/wp-content/uploads/technotes/TN2_AFM_to_MAF_Conversion.pdf

The price of the second one gets pretty close to the order of magnitude of the price of an aftermarket ECU so I will not further investigate it.

Please let us know in case you know other.

I posted somewhat in the Pilot Engineering support forum and I’m waiting for an answer.

They are based in Kyrgyzstan and they just recently had a military conflict with a neighbouring country, so I’ll give them some time credit.

Meanwhile I'll try to find some time to have a look at the software and how to deal with the IAT sensor in their setup.

One will need a MAF regardless of the converter used, and for sake of simplicity it would be best if we all used the same.

Could we agree upon a MAF to be used for the K100 engine?

There is s few Bosch AFM listed in this catalogue

https://www.bosch-ibusiness.com/media/images/products/sensors/xx_pdfs_1/sensors_i-business.pdf

Keep a local copy of the pdf because these links appear to change regularly.

A 1000 cc 4-stroke engine at 8000 rpm assuming a volumetric efficiency of 100% will pump 4000 litres/min. At 1.25 g/l air this would be 5 kg/min or 300 kg/h.

I would suggest the 0 280 218 440 with a measuring range till 480 kg/h. It's the smallest in the catalogue anyway. The 60 mm outer diameter will probably connect to the existing duct and fit in the air filter box.

Any suggestions or remarks?

https://www.k100-forum.com/t11055-bosch-air-flow-meter-restoration-summary

but it is better to make a separate thread for it.

Using MAF on the K100 has been tried before but I couldn’t find any working (and driving) example.

Let us know if you do.

The K100 uses a vane-type airflow meter (AFM).

Mass airflow meters (MAF) didn’t exist in the early eighties or were expensive or unreliable I don’t know.

First MAF versions used a thin heated wire and can I imagine they were somewhat fragile.

Present-day MAF use a hot film and that looks much more robust.

Nowadays MAF are common, inexpensive and reliable, and they offer an attractive alternative to the AFM.

Prices vary from roughly 25 to 150€.

Compared to AFM, they cause less restriction of the airflow, they are less bulky and they are available on the market, while the original AFM is available as second hand item only.

Disadvantages of the use of a MAF. The measuring element can accumulate dirt from a poor air filter or oil from an over-oiled cotton gauze filters (K&N and co), causing erroneous measurements.

There is a major challenge in using a MAF instead of AFM. They have a different output signal versus airflow and thus require another ECU or a signal converter.

Aftermarket ECU is rather expensive and absolutely not plug-and-play.

It’s the signal converter way I would like to explore. It’s less invasive compared to the ECU path.

Is it worth ditching the AFM in favour of a MAF?

Depends what you want. If you’re happy with your bike and you don’t like experiments than don’t go for it. As such, the K100 was and still is a very good design.

For me it’s a technical challenge and I love that.

As the MAF will cause less resistance to airflow it should in principle yield some extra power, although I don’t expect to gain more than a leg of a horse.

So one will need a signal converter to modify the MAF output signal to the AFM input of the ECU.

There are probably more but I found two companies offering this as a finished product

http://max.pilotpowersupply.com/product/pilot-vaf-to-maf-converter-with-a-bluetooth-interface/

https://splitsec.com/wp-content/uploads/technotes/TN2_AFM_to_MAF_Conversion.pdf

The price of the second one gets pretty close to the order of magnitude of the price of an aftermarket ECU so I will not further investigate it.

Please let us know in case you know other.

I posted somewhat in the Pilot Engineering support forum and I’m waiting for an answer.

They are based in Kyrgyzstan and they just recently had a military conflict with a neighbouring country, so I’ll give them some time credit.

Meanwhile I'll try to find some time to have a look at the software and how to deal with the IAT sensor in their setup.

One will need a MAF regardless of the converter used, and for sake of simplicity it would be best if we all used the same.

Could we agree upon a MAF to be used for the K100 engine?

There is s few Bosch AFM listed in this catalogue

https://www.bosch-ibusiness.com/media/images/products/sensors/xx_pdfs_1/sensors_i-business.pdf

Keep a local copy of the pdf because these links appear to change regularly.

A 1000 cc 4-stroke engine at 8000 rpm assuming a volumetric efficiency of 100% will pump 4000 litres/min. At 1.25 g/l air this would be 5 kg/min or 300 kg/h.

I would suggest the 0 280 218 440 with a measuring range till 480 kg/h. It's the smallest in the catalogue anyway. The 60 mm outer diameter will probably connect to the existing duct and fit in the air filter box.

Any suggestions or remarks?

__________________________________________________

* Train dogs. Teach people.