1

Rebuilding a K Odometer using inexpensive eB*y gears- a (rough) guide Sat Jun 13, 2020 2:18 am

Rebuilding a K Odometer using inexpensive eB*y gears- a (rough) guide Sat Jun 13, 2020 2:18 am

StandardK

Gold member

Hi all,

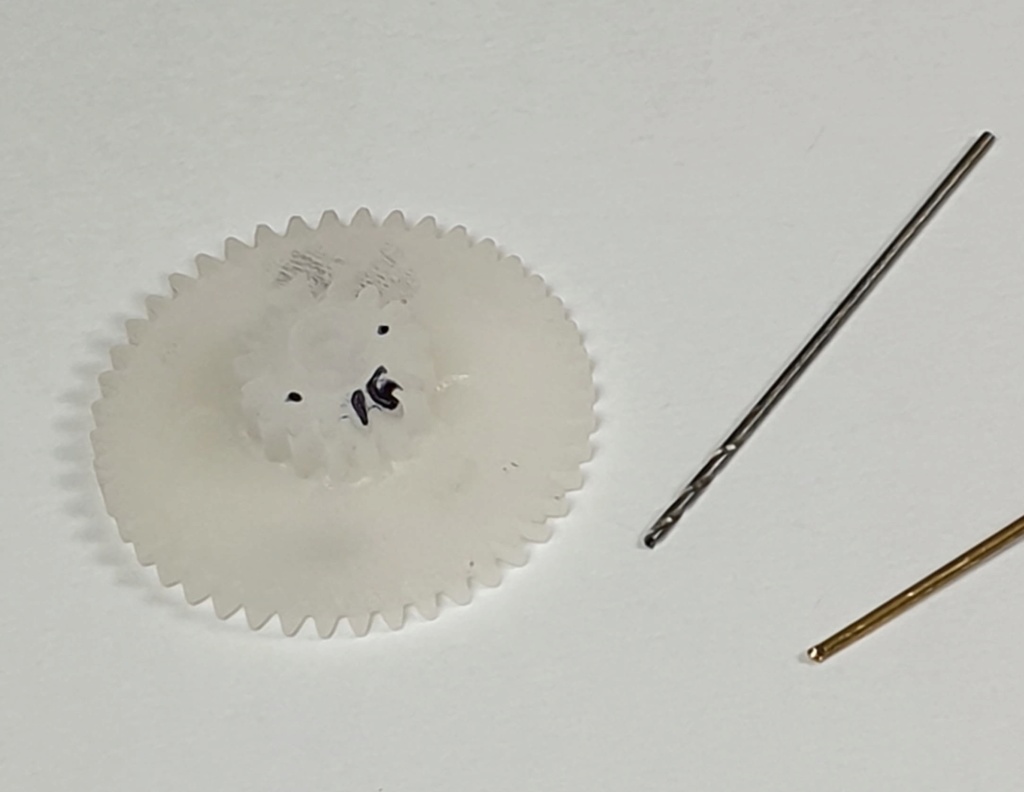

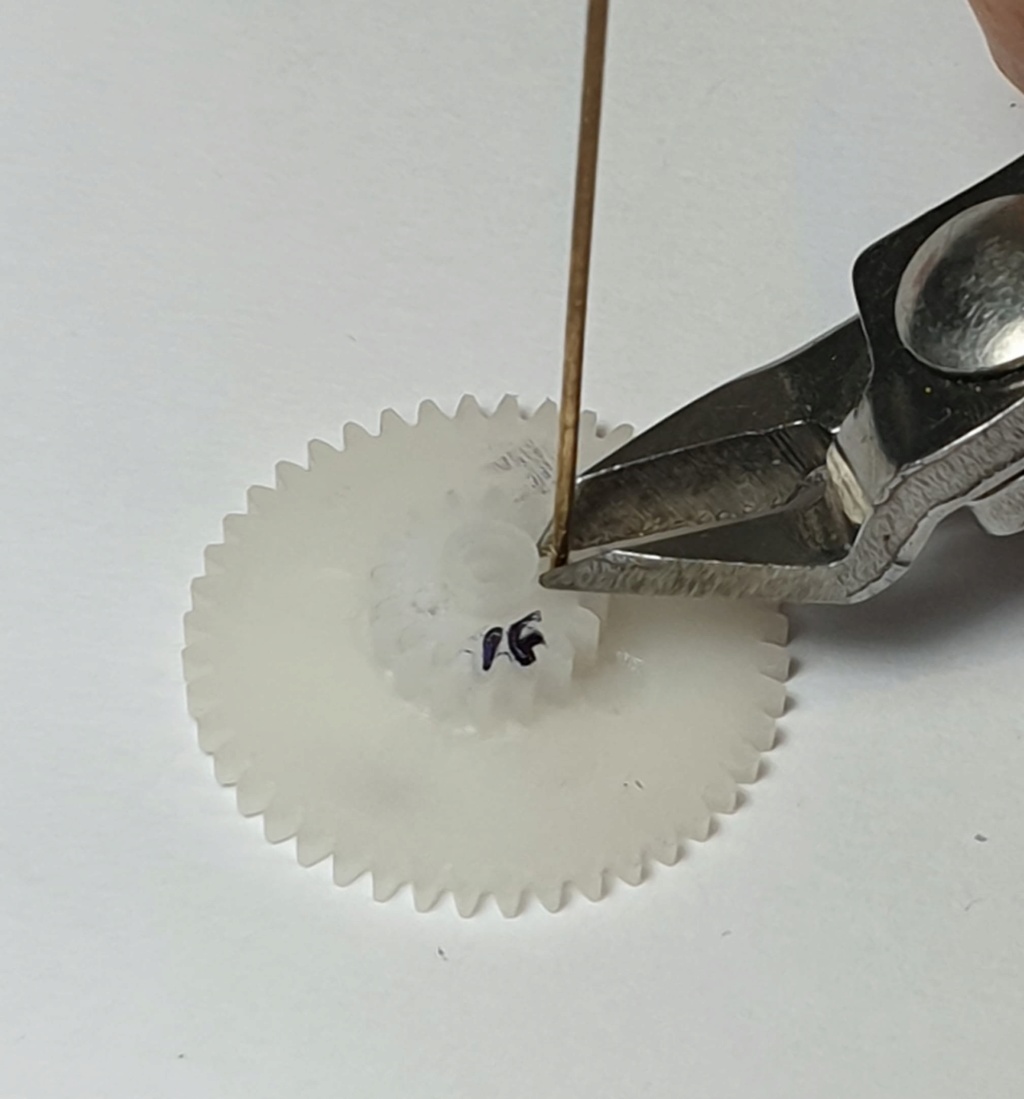

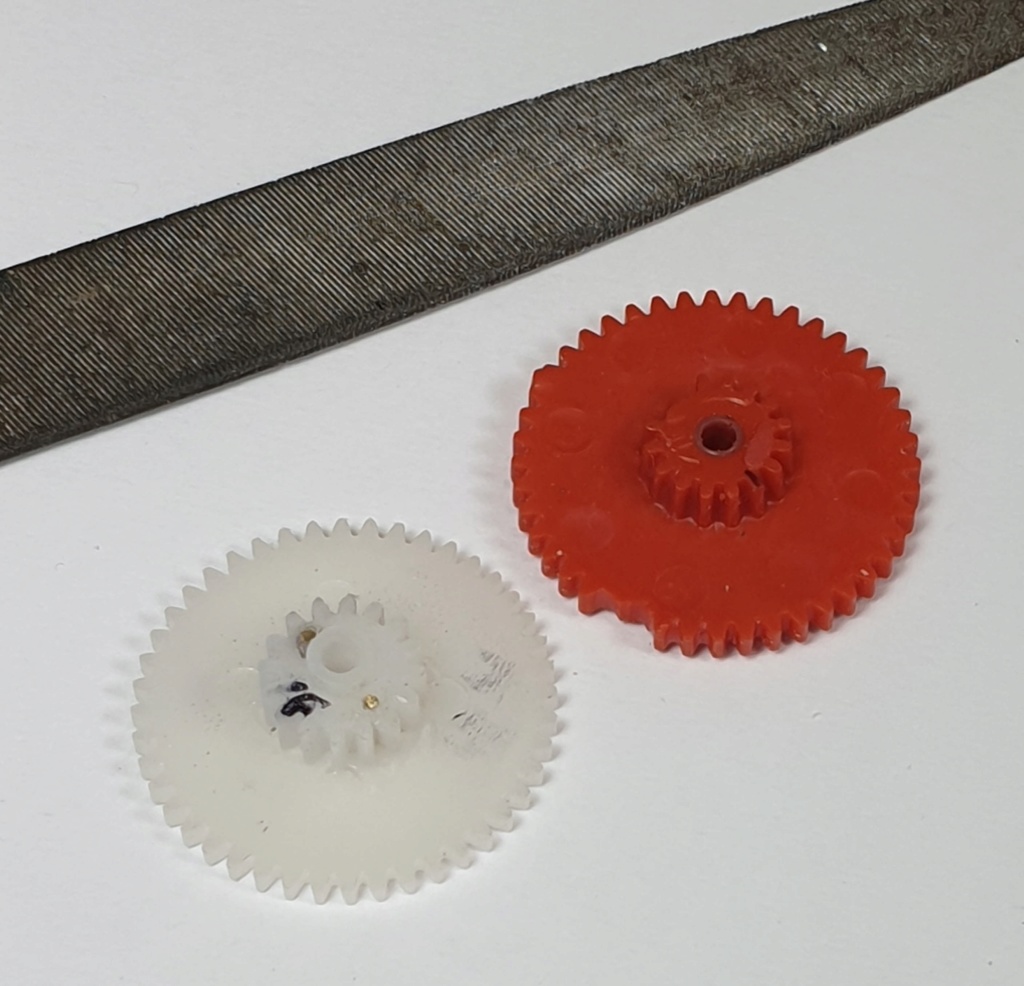

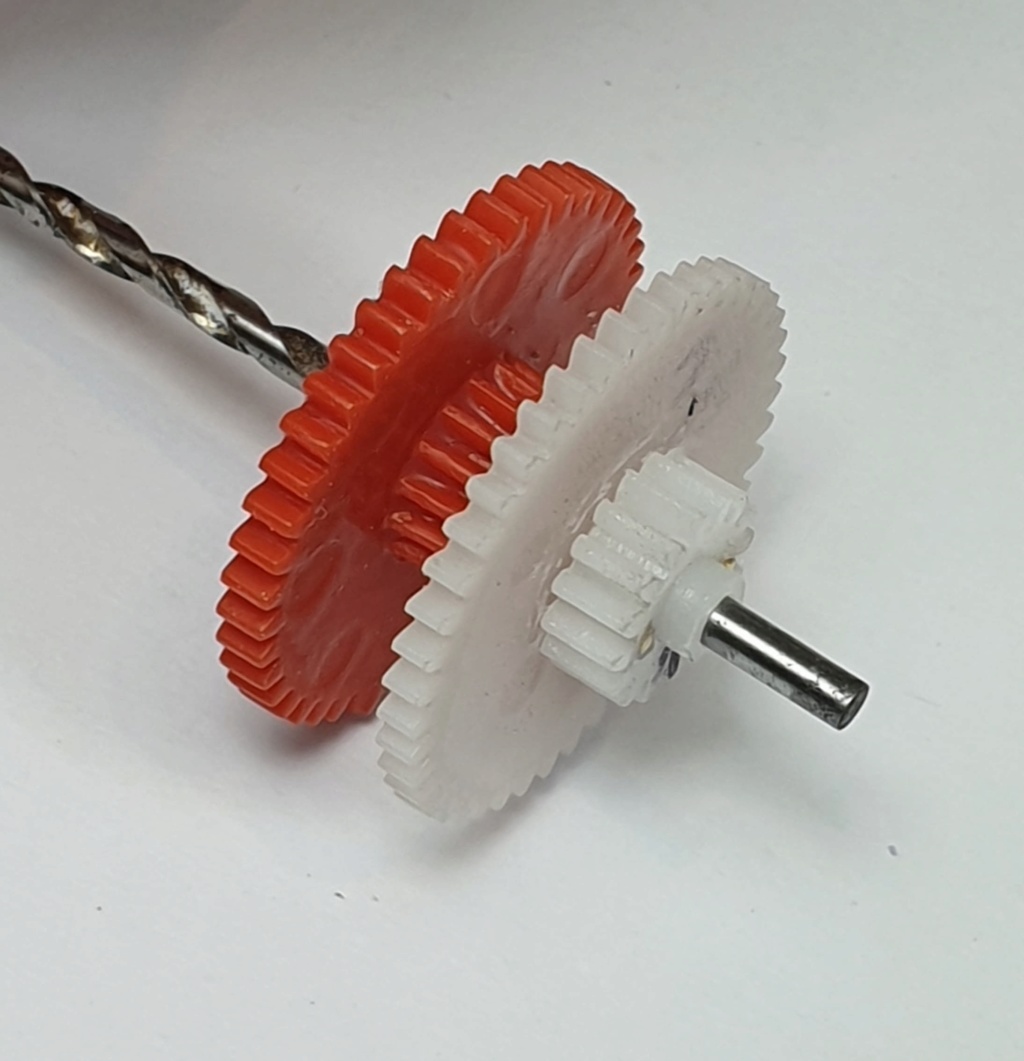

I thought I would post up a guide to replacing the notorious stripped OEM gears on a K Odometer, using the cheap plastic gears commonly found in generic hobby sets on fleaBay or in electronics/hobby stores. The repair as shown here cost a grand total of $6 AUD (plus a few hours of your time)- they were kindly supplied by Martin W for the Project. It requires no specialist tools, just a cordless drill, small file, superglue, some small diameter brass rod & some teeny drill bits.

I also begin by a disclaimer stating no warranties or guarantees for the following repair if attempted! But hey, for $6 it’s worth a try, no? I also offer apologies if this info is already “old hat” news.

I also offer apologies if this info is already “old hat” news.

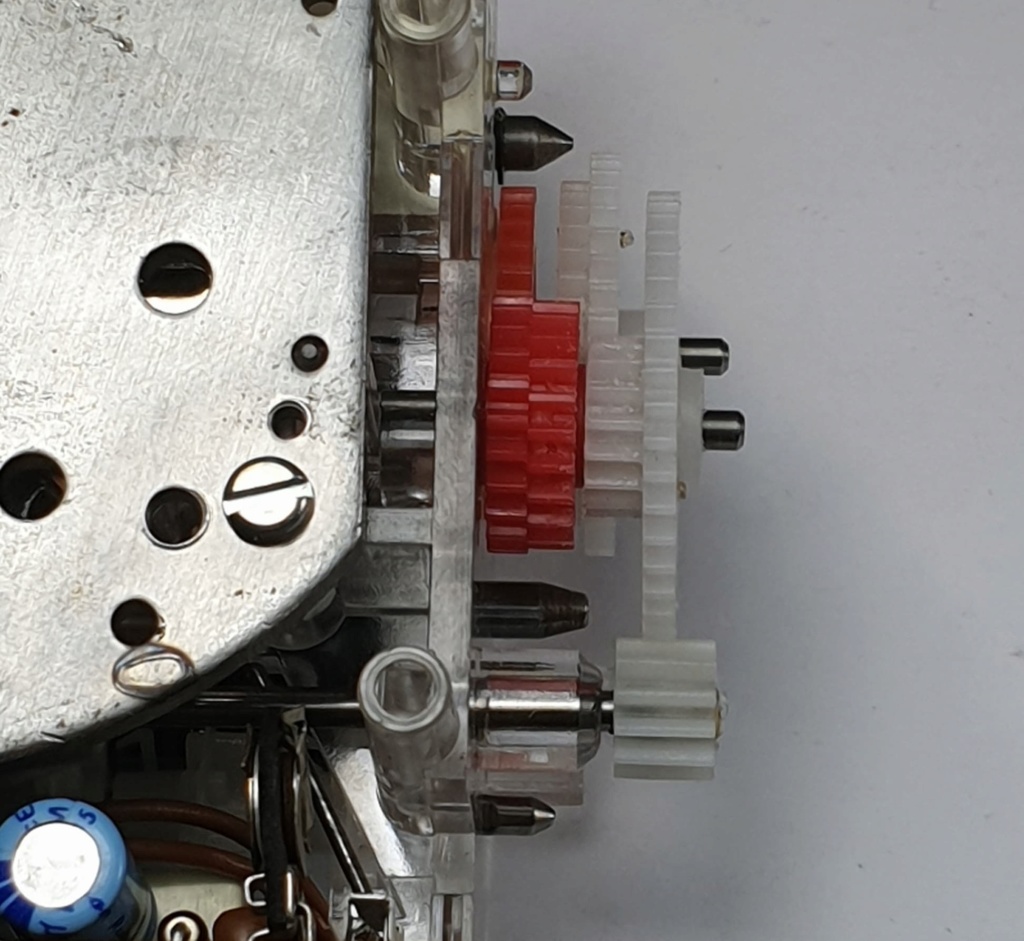

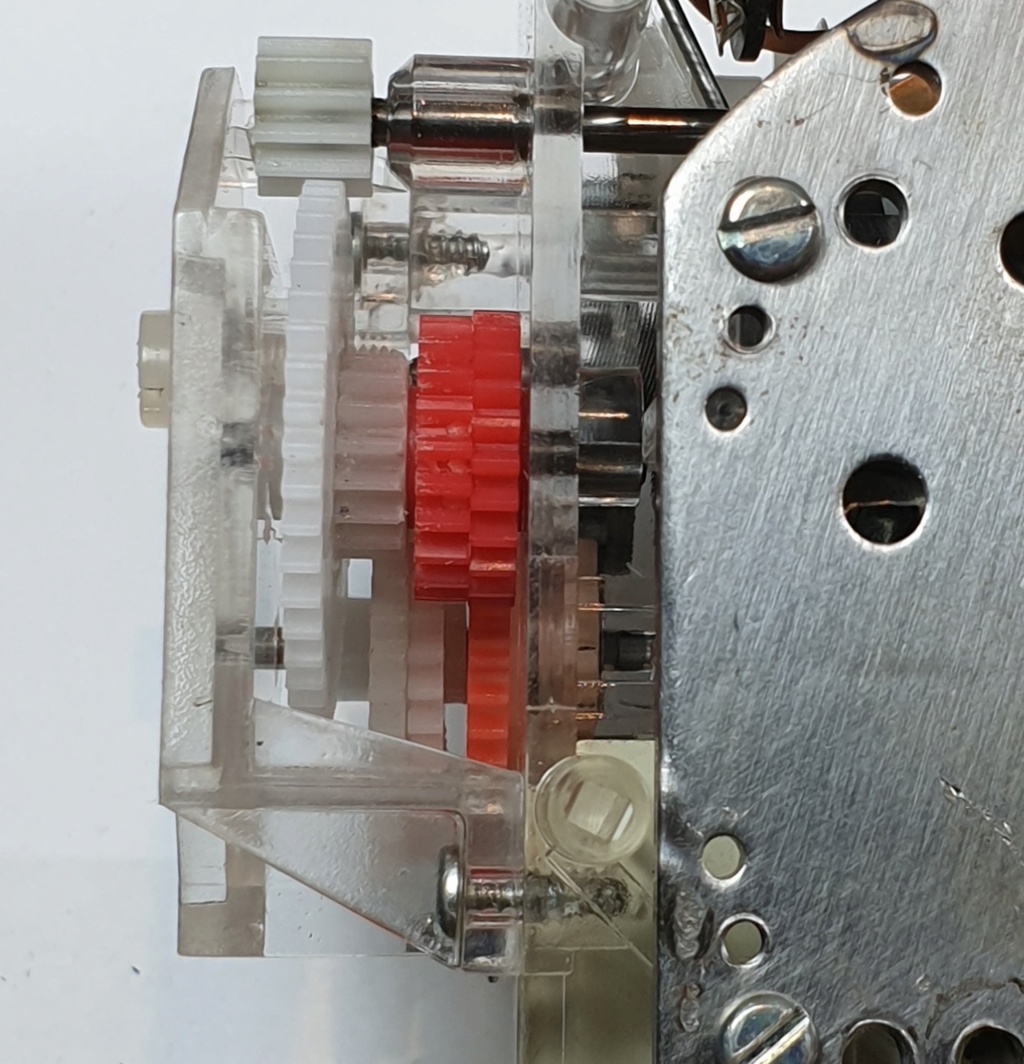

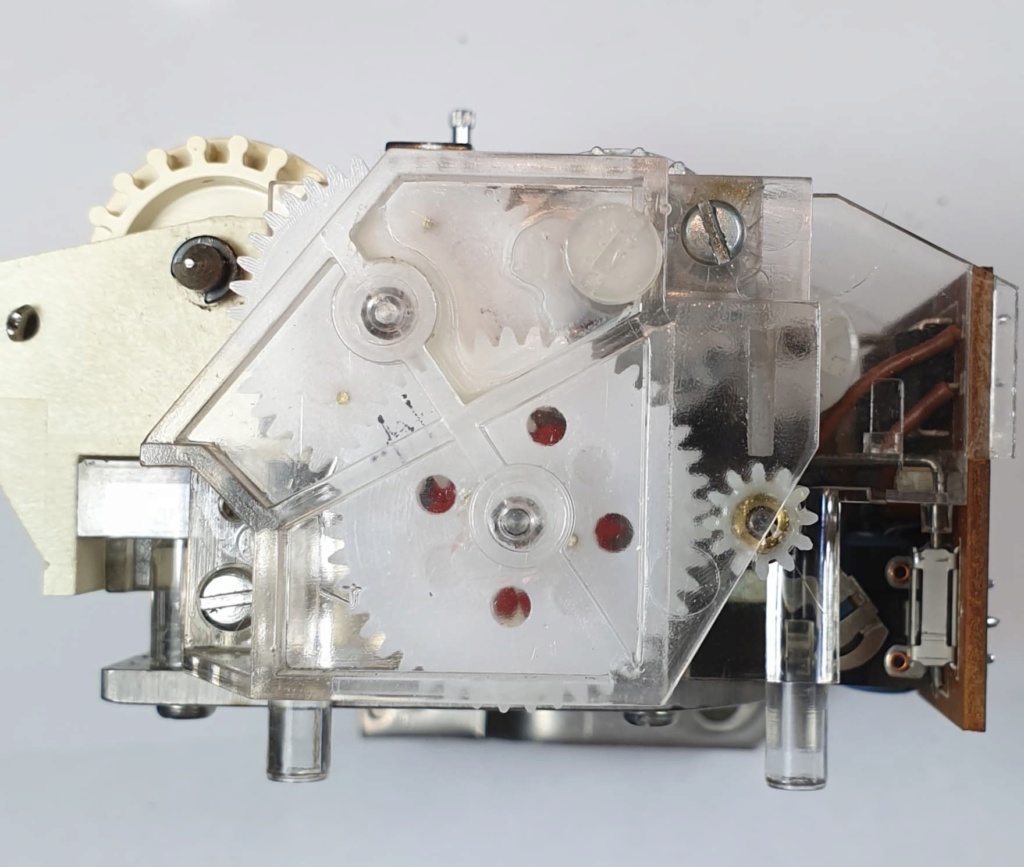

I won’t delve into removing the speedo pod & Odometer as that’s already been covered elsewhere on the forum. We start with the following scenario, all too common so I’ve read...

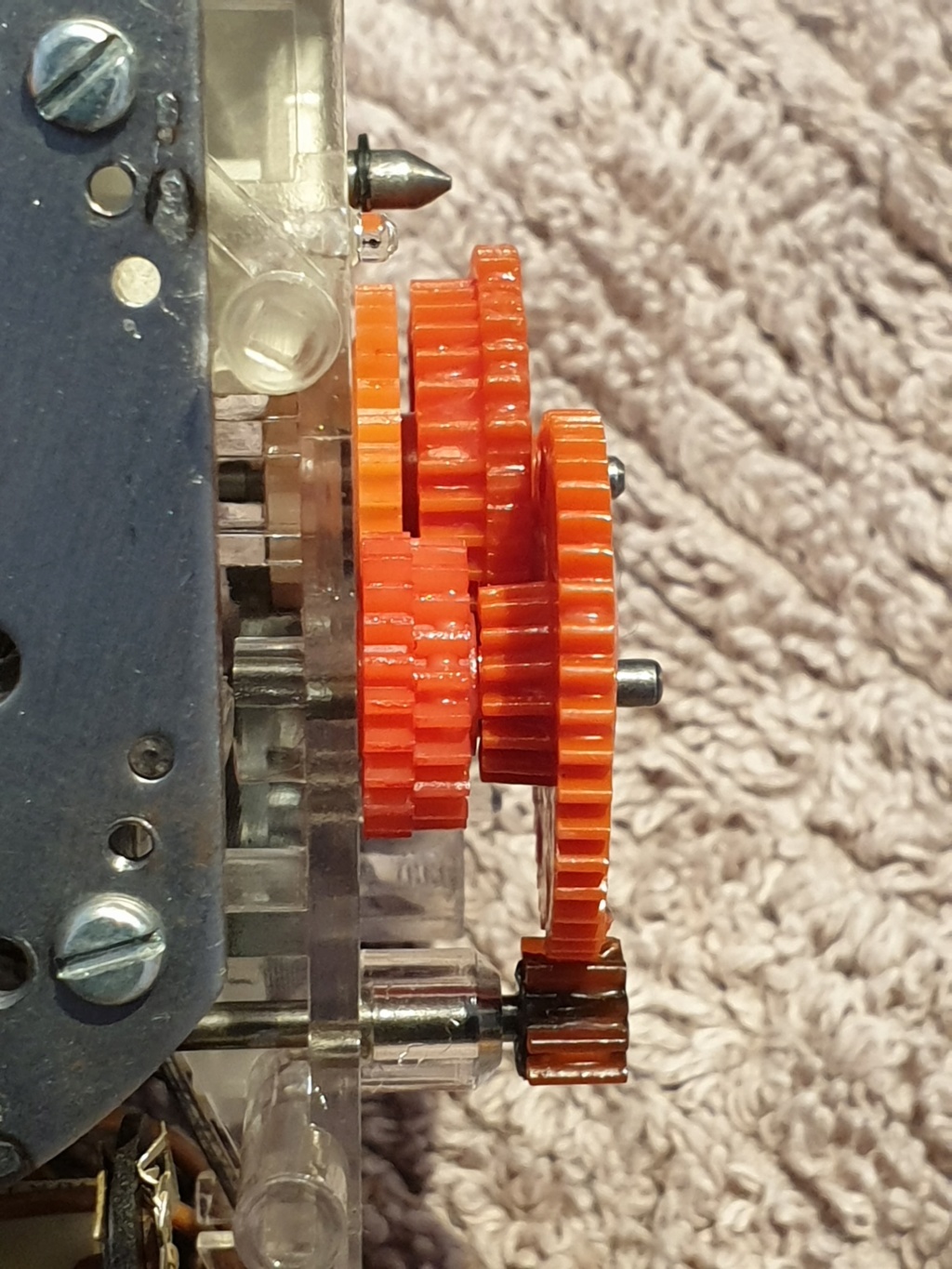

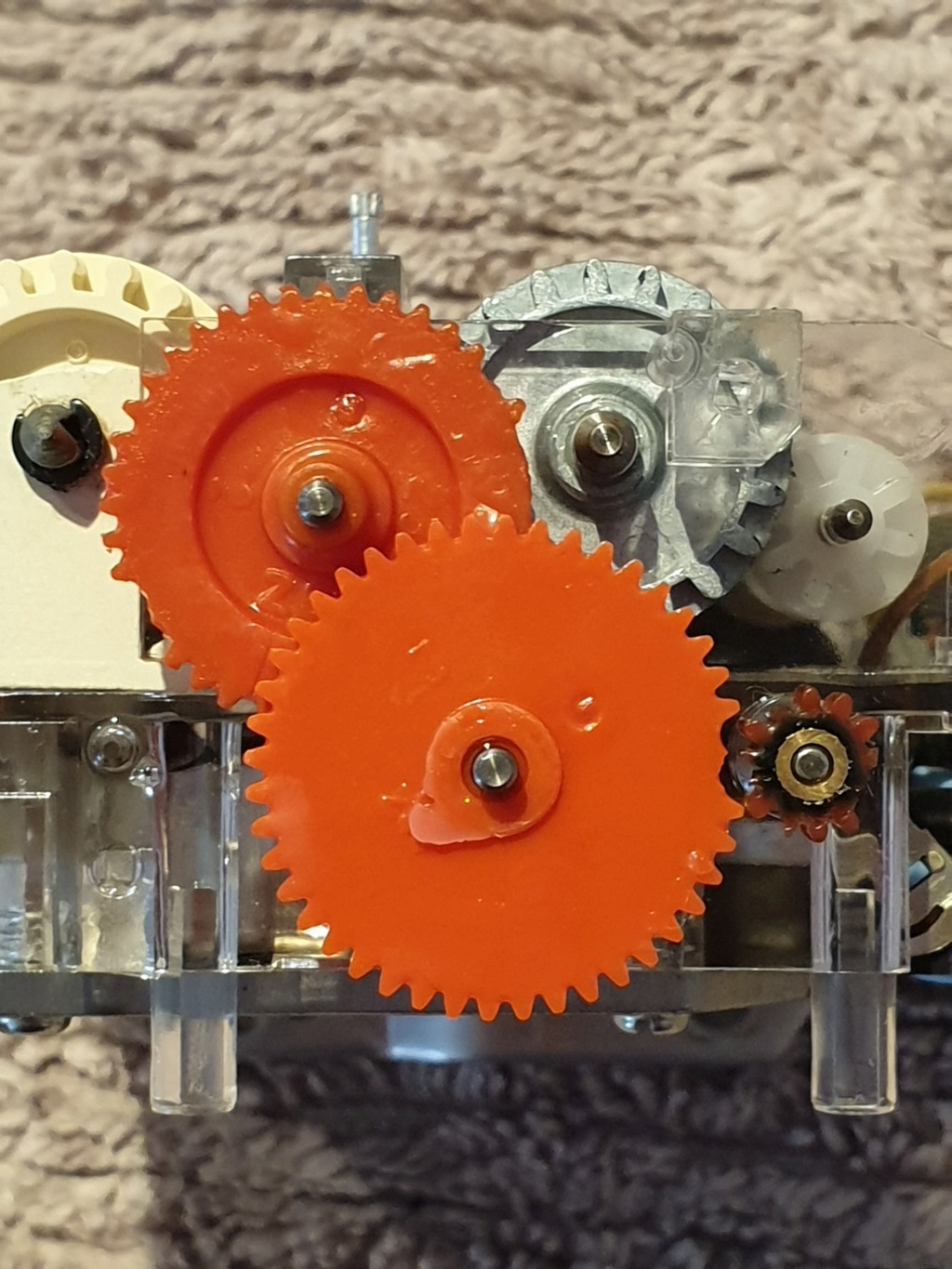

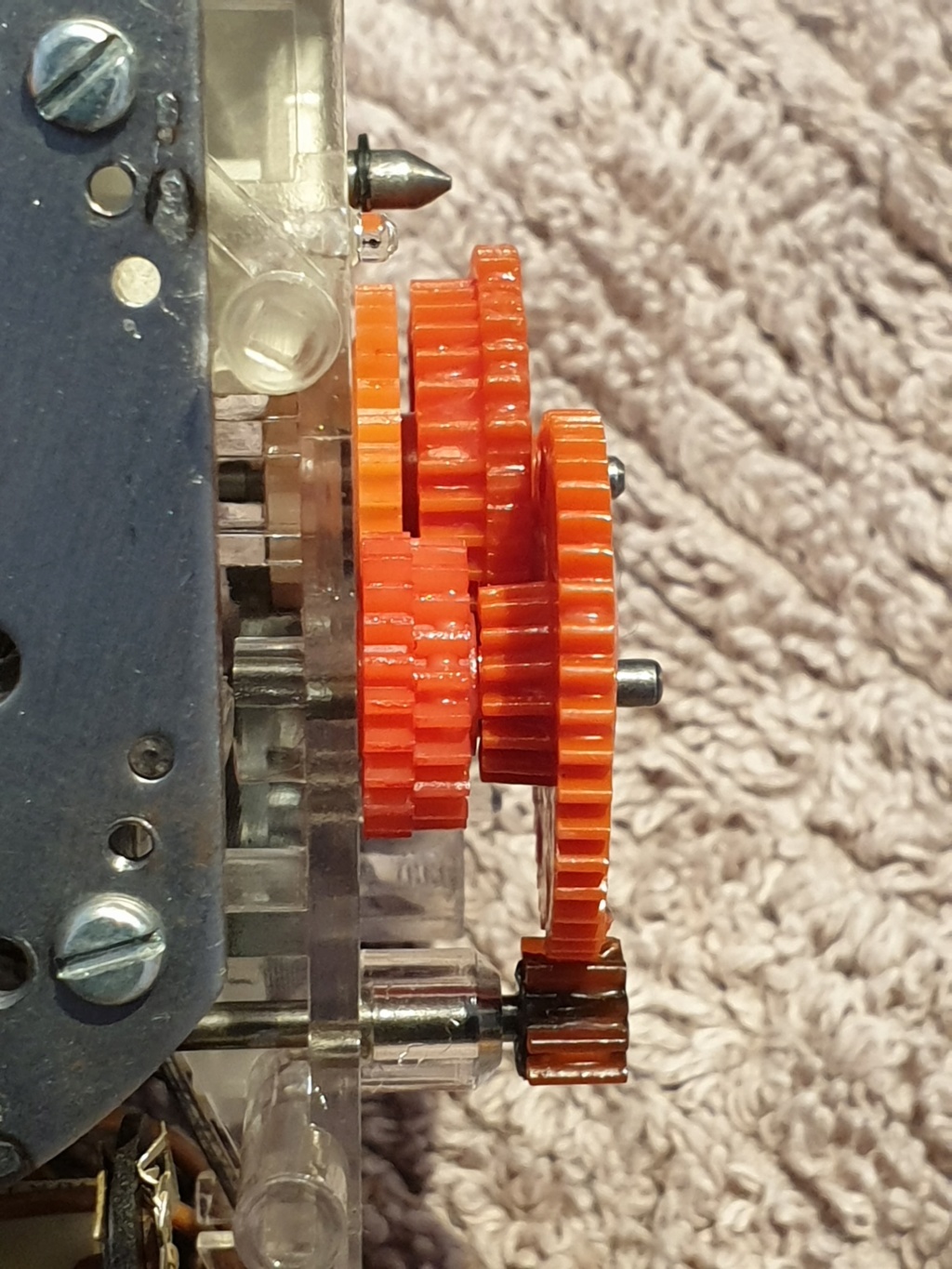

In my case the 12t driving gear was stripped along with the 34/40t & 16/44t. The 11/33t & 22/23t gearsets in this instance were ok, possibly due to not being contaminated with the lube that kills the OEM gears.

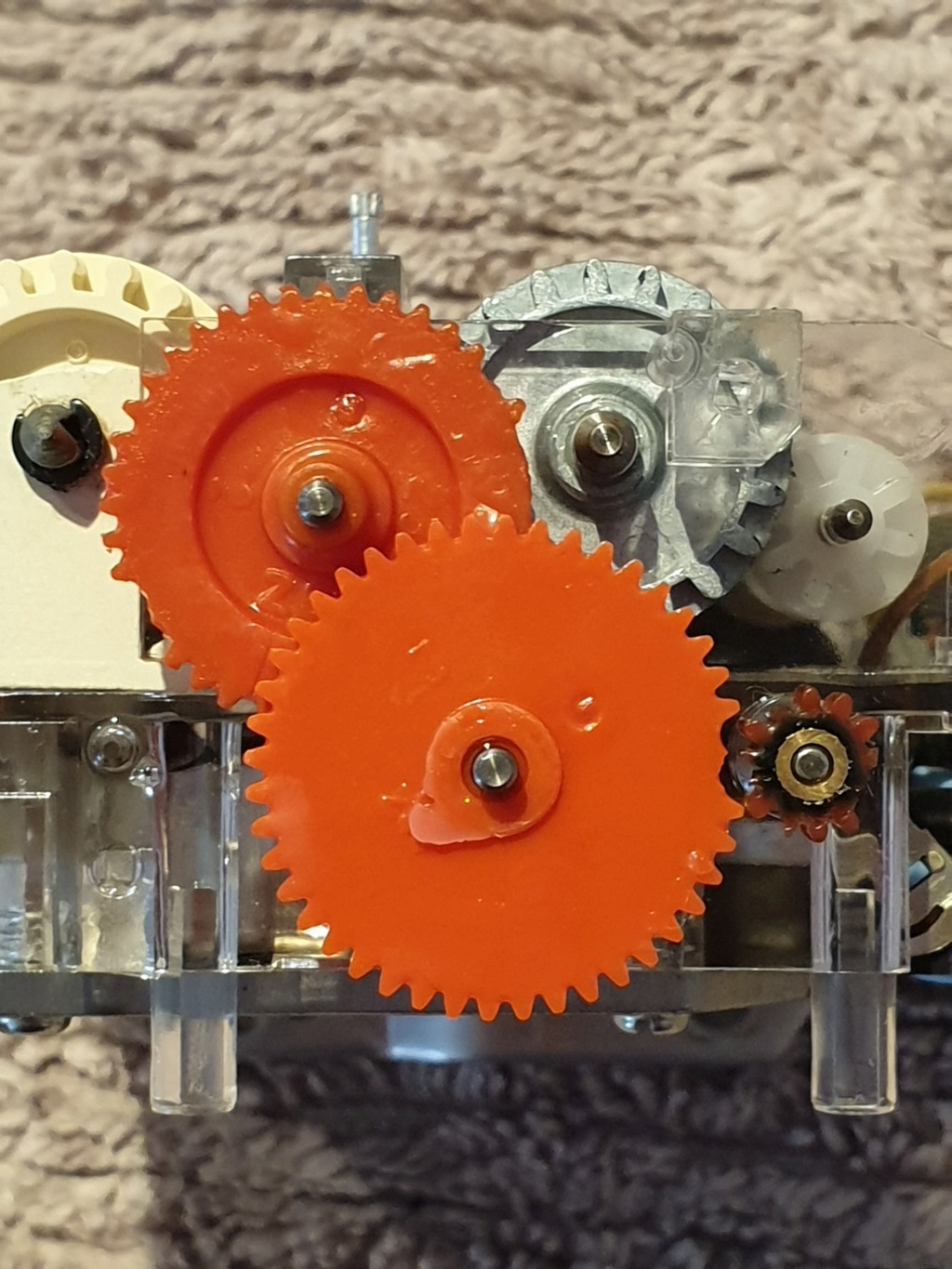

So, out of the packet of generic nylon-type cheapy gears the correctly toothed gearsets were selected. As it’s near impossible to source the double sided gears we’ll be joining two single sided gears. As this is an Oz-based K, the tooth count will be obviously different for Euro & U.S Odometers.

I thought I would post up a guide to replacing the notorious stripped OEM gears on a K Odometer, using the cheap plastic gears commonly found in generic hobby sets on fleaBay or in electronics/hobby stores. The repair as shown here cost a grand total of $6 AUD (plus a few hours of your time)- they were kindly supplied by Martin W for the Project. It requires no specialist tools, just a cordless drill, small file, superglue, some small diameter brass rod & some teeny drill bits.

I also begin by a disclaimer stating no warranties or guarantees for the following repair if attempted! But hey, for $6 it’s worth a try, no?

I won’t delve into removing the speedo pod & Odometer as that’s already been covered elsewhere on the forum. We start with the following scenario, all too common so I’ve read...

In my case the 12t driving gear was stripped along with the 34/40t & 16/44t. The 11/33t & 22/23t gearsets in this instance were ok, possibly due to not being contaminated with the lube that kills the OEM gears.

So, out of the packet of generic nylon-type cheapy gears the correctly toothed gearsets were selected. As it’s near impossible to source the double sided gears we’ll be joining two single sided gears. As this is an Oz-based K, the tooth count will be obviously different for Euro & U.S Odometers.

Last edited by StandardK on Sat Jun 13, 2020 2:50 am; edited 2 times in total