John Britten is a hero of mine, up there with Dunlop, Hailwood...the usual roll call I suppose.

Anyway, the exhaust -

These are some of the leftovers. I started with the standard cans from a Triumph Street Triple, which mount as a pair high up either side of the tail unit on the OE bike. The complete one in the above pic is the RH can, which has the wrong bracket orientation (the K75K can goes on the LH side) but the correct angle of dangle for the link pipe. Soooo, it was just a case of disembowelling a LH can (the baffles are cheapo mild steel - unbelievable), cutting off the front end/link pipe, and replacing it with the front end/link pipe from a similarly butchered RH can. The finished item (below pic) just has a perforated pipe down the middle instead of the baffled chambers.

The heat shield is a bit of a bacon slicer with the front overhang, but that's how it was on the OE bike. The link pipe is just a 90 bend joined to a 60 bend, which then replaces the too-small OE link pipe welded to the silencer front end cap.

Today (yes I've managed two days, well, afternoons working on it this week - yay) I've mostly been getting the clutch mechanism all wrong..

The big and clever high level exhaust has elbowed the clutch actuation arm out of the way, so I shortened and re-routed the OE arm, and made a new bracket for the cable, which mounts on the former battery tray mounting holes. (Yep, the new super-duper lithium battery - which weighs the equivalent of two hydrogen atoms - is going to be relocated somewhere more suitable to its puny size - probably inside the handlebar tube or something - where it will be held in place with a cork...)

Anyway, after making sure the butchered actuation arm maintained the same lever length as the OE (only smart people allowed in

this shed) I rustled up a cable, connected it up, pulled the clutch lever and....nothing. Turns out that the F800s clutch lever currently deployed to this hare-brained project has a lever length of 26mm, compared the good 'ole K's 35mm. Turns out too, that dumb asses have been in this shed all along...

Anyway, milled a new end for the actuation arm, which is proportionally shorter, and it now all seems to work okay. Still not got the mighty amount of release movement of the OE setup, but that's because the OE K clutch lever is set a bit further from the bars and so has a longer stroke.

Maybe I should have checked all this beforehand, maybe.

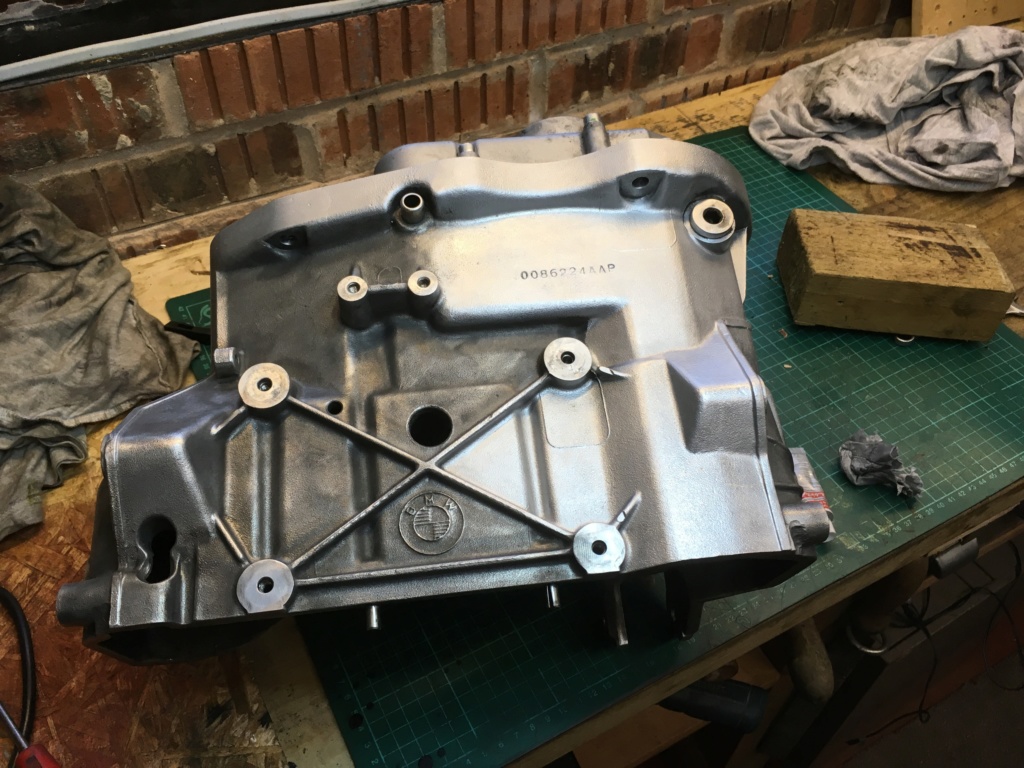

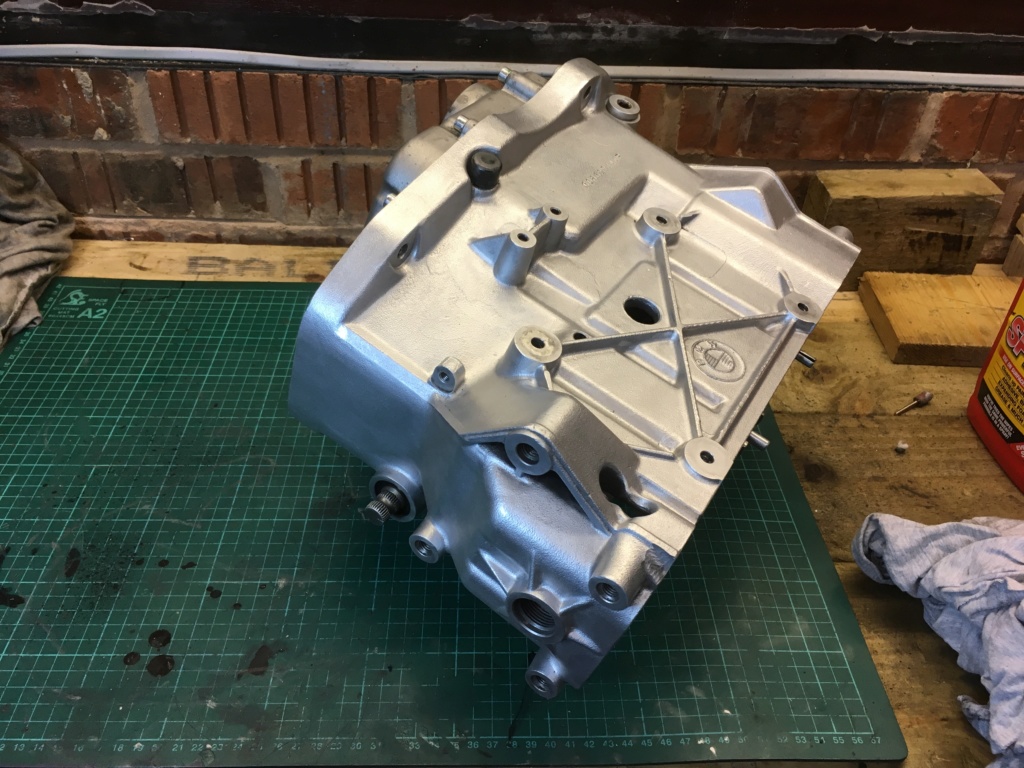

Got a query though. I've been googling this and other forums but not really cracked it. The current assembly has a K75 clutch (it came with the engine), but a gearbox which I think is from a K100. The pushrod seems to release the clutch fine, but I know that the K75 is supposed to have its own pushrod. Is this anything to do with the clutch diaphragm spring- do I need to fit one? All clues appreciated, cheers.

Re: K75kforkurz Sun Apr 15, 2018 5:24 am

Re: K75kforkurz Sun Apr 15, 2018 5:24 am