Hello all, back again, sorry for silly late reply.....

Well, I have spent some time examining the parts from my engine, all the wear marks are the same as the photos in this thread, very consistent.

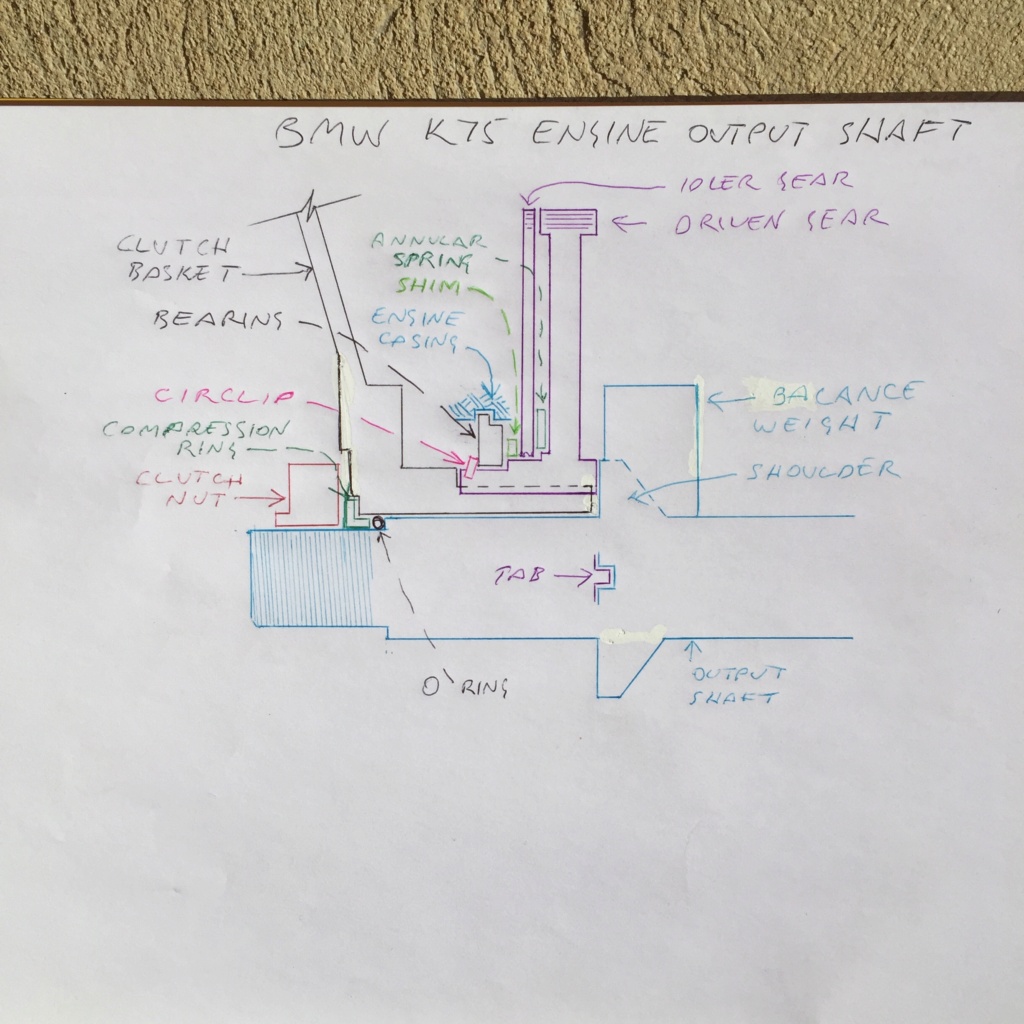

Hi Rawdonball, sorry my explanation was as clear as mud!, I can't seem to post photos yet, do I need a certain number of posts first?, The parts I was referring to, if you look at the exploded drawing in the Haynes manual, output/balancer shaft K75;

Part number 5, the balance/output shaft, the faces where it mates against part number 6, the drive gear, my parts show a polished witness mark on both faces, more pronounced on the balance/output shaft, due I guess to the drive gear being so much harder.

I spent about an hour lapping the two surfaces together with some valve grinding paste, so darn slow due to the minimal movement allowed by the gear dogs to balance/output shaft grooves.

I ended up with about twice the contact area, so am hoping it can only help to keep the two parts from moving, semi rotary movement, once the clutch housing retaining nut is fully tightened.

Point seven five, I think you have got it right, I could not find any thing wrong in my engine, apart from the polished witness marks mentioned above, which I think is proof positive that movement was occurring in that area, allowing the gear dogs to clatter in the shaft grooves.

I did find a bit of roughness in the alternator bearing, the drive bearing that fits in the bell housing, which I will replace, other than that, all seems very good, I took the parts to show the boss of our local engineering shop, he could see no issue with wear, just a few polishing marks he said, but did agree on the witness marks on the balance/output shaft to drive gear faces.

He did comment on not being surprised as to the design, the loose fit of the dogs and grooves, he said its a modern way of design and manufacture, he said so many engine parts these days rely simply on the tightness/torque of the retaining nut/bolt, things such as camshaft sprockets being held in tapers with no key-ways! etc.

So, now to re assemble, keep those faces spotlessly clean!, I have a new anti backlash spring, and am re using the thrust washer, which has clearance to the large bearing, numbers 10 and 14 respectively, in the above mentioned Haynes drawing.

The old and new anti backlash springs look identical!, have not tried to measure the tension though.

Thanks for the update point seven five, very heart warming to hear you now have a quiet running engine!, I shall hopefully be able to report in due course the same outcome with my engine!.

I wish I could of posted some photos, but there does not seen to be an option to attach them, I am guessing I do not have enough posts yet?.

All the best,

John

Re: Engine Clatter Tue Mar 15, 2016 1:58 am

Re: Engine Clatter Tue Mar 15, 2016 1:58 am

The bottom line is that I'm going to just re-install the shim as it was and be done with it, unless of course someone can feed my neurosis with something like 'Have you been adding an appropriate amount of blinker oil?'

The bottom line is that I'm going to just re-install the shim as it was and be done with it, unless of course someone can feed my neurosis with something like 'Have you been adding an appropriate amount of blinker oil?'