Gearbox selector drum cam follower fix

Old Gertys gearbox had suffered an input spline failure , stripping the spline core out of the clutch plate , with sad to say, sharks toothed appearance of the shaft spline , due to poor or flushed out lubrication I suspect .

The clutch plate itself was not dully worn at all other wise , as I had changed it some 50,000 ks ago (about 3.1/2years ago )

So the reason for the change to a “new to me” gearbox .

upon installation I found it very hard to select neutral

But achievable , with patience .

So this has lasted me for a while but issues are getting worse .

Small issues about first , second selection were always present , but after a fair while now I find it hard to get past second gear , even worse second gear jumps out of location back to first , or close to ..perhaps back to neutral .

If I can get past 2

nd gear ( and I have found a way , but not always successful ) 2 times out of 10 third gear will bounce- fall back to a false neutral . once past 3

rd gear all is good , or at least third gear and up is always reliable and 5

th to 3

rd is also reliable ..

I fear on top of what I have found in gertys relatively pristine gearbox , that I may have also bent the first – second gear selector fork in the new to me box …blast . but perhaps this was an earlier event in any case ????

Fortunately Gerty will load up from a third gear take off , although keeping the revs low whilst taking off , I hope wont wear the friction plate too much .

Which has led me to investigate the phenomenon a little more closely.

Before I go and refurbish Getrys original gearbox with new bearings, seals and a good looking input spline , (a gift from one of our good mates Seanii ) from a few years ago

I thought to investigate the gear drum to see if I could find some issues , fortunately Getrys gearbox was always a good shifter , for want of a better word ,

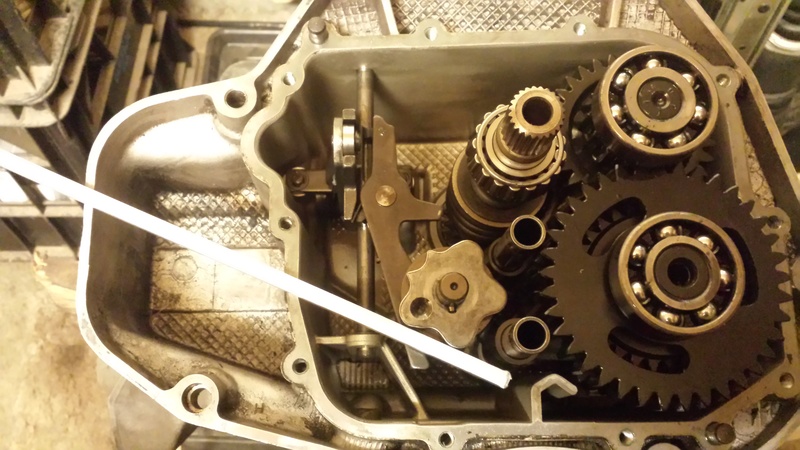

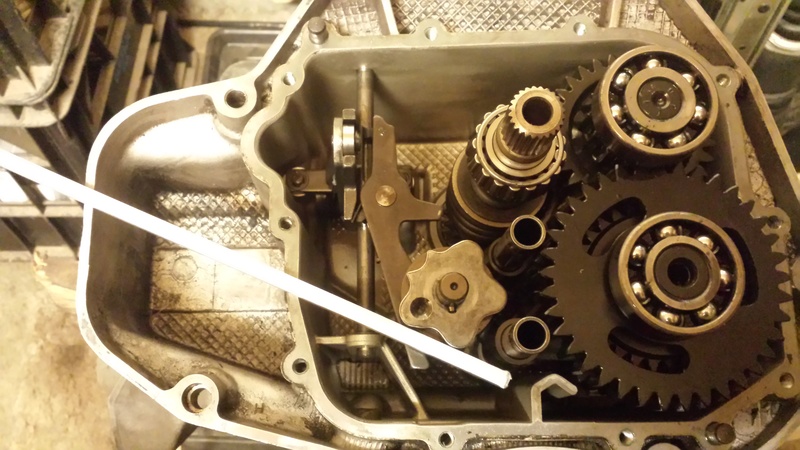

Upon removal of the cover plate and first thing that can be noticed is the cam on the gear selector drum.

I notice an interesting wear of the locator pin in the gear selector drum cam follower

Of quite a few degrees . which I imagine would have some significant effects Including the issues that I am experiencing on the replacement gearbox .

Its almost as if the selector pawl on the drum cannot reach the next pin location to pull third gear into action and the cam follower arm cannot assist in locating the correct location on the gear selector drum once selected

Heres a few pics I have taken of gertys selector drum cam .

Notice the difference in binding in one direction to binding in the other direction ,due to movement of the pin in the keyway of the cam .

There is obvious movement in the pin locating the cam to the drum shaft

With both wear in the pinned section within the shaft and the pin that fits in the keyway.

By replacing the pin with a new 3mm drill bit as a test ,there is still a fair bit of movement , I measure the drill at 2.97mm and the pin at 3.02 mm but there is a fair bit of rotational movement

The parts diagrams say that the pin is 3mm x 6mm .

I imagine it is supposed to be round and I guess hardened ?

The cam follower on the selector shaft has quite large lobes between the gear positions for third , fourth and fifth gears . and a relatively low deviations first to second through the neutral position .

I could be hoping that this wear is more prevalent on the “new to me” gearbox and surmise that the radial movement noticed on the cam follower pin is not allowing the cam follower to locate correctly at first ,neutral and second locations , further complicating the reach of the gear selector paul to the grab pins on the selector drum .

On Gertys gearbox the locating pin itself is showing a great deal of wear , with a very squarish appearance on the cam keyway end . which needs replacing in any instance .

What to do ?

A few solutions come to mind .

1 > drill an new pin location hole to 1/8 inch dimensions and utilise the same length new pin at 1/8

th inch thickness + file out the cam key way to 1/8

th inch

2> drill a deeper hole, to 6mm depth at 3mm diameter and install a new 3mm x 9mm pin

3> drill a 6mm deep hole to 1/8

th inch diameter and install a new 1/8

th diameter pin x 9mm long + file out the keyway in the cam

the third option sounds the best to me

which I have done with satisfying results and very little movement at all now

I guess that this fault could be the demise of a few second gear sets and the cause of some bent selector forks for many older and high kilometre gearboxes .

I think the find will prove interesting as I delve into the “new to me” gearbox once removed …perhaps its been sitting for far too long and crud has built up on the cam follower roller and mechanism , as I observed on a gift gearbox (from Alby ) with some typically cruddy roller and claw- pawl mechanism parts evident .i guess the worn locating pin is also an repairable issue as its not particularly hard to clean these parts up ..but if not observed in the first place ..could this be a contributing factor ?..

Just food for thought

And I hope a solution to someone out there

Re: 85 rt resto ...my attempt ...hey im not into making a show bike ... Sun Aug 14, 2016 12:29 am

Re: 85 rt resto ...my attempt ...hey im not into making a show bike ... Sun Aug 14, 2016 12:29 am

lol , yes your probably right stan

lol , yes your probably right stan

(Applies to ainsjac's comment and to Charlie's work.)

(Applies to ainsjac's comment and to Charlie's work.) ... um ... I think ?

... um ... I think ?