Hi,

I just finished installing a K1100 electric windshield on my 1988 K100RT. This was a great success, not the least in gratittude to Crazy Frog (Bert) for his patience in answering my questions and providing valuable schematics. I thought I'd document my installation in case others persue the same install and want to see an alternative solution to the problems that will be encountered.

Parts List

I obtained all the parts needed for the installation through a private sale. These BMW specific parts are detailed above in Bert's description but I'l reitterate:

- windshield mechanics and carrier base

- Lexan windshield

- console (AKA dash)

- all screws and bolts

Windshield Control Circuit

In addition, it is necessary to construct a circuit that switches the correct polarity and voltage to the windshield motor. These components include (2) 10A 12VDC 1FormC [SPDT] relays, 18 AWG stranded hookup wire, 6 pole AMP connector, breadboard PC card 1.5" x 2", PC threaded standoffs and screws (I used PC motherboard standoffs from a scrap PC), SPDT momentary contact, centre off switch (17mm x 31mm).

I chose to use miniature PC mount relays on a circuit card rather than automotive relays as Bert chose mainly because I wanted all the control circuit on one small ealily replaced unit. It makes debugging problems easier. The card is a standard breadboard PC card with 0.1" contact spacing. My circuit is shown below along with the finished card:

(Thanks Bert; I made some modifications to your original)

The schematic of the relays I used is below:

The electrical operation is really straight forward. The circuit has two logical parts -- the lift/lower relay control logic and the motor control logic. Refer to the diagrams above.

First the lift/lower relay control logic description. Battery power is fed to the center of the Window Adjust Switch through its common contact (wire L/Y) and each side of that switch goes to one side of the coil of each relay (pin 85). The other side of each relay coil (pin 86) returns to ground through a given microswitch (UP switch & DOWN switch). Let's say the operator presses the window adjust switch for UP motion. Current will flow through the Window Adjust Switch to the lift relay coil, continue through the Up (micro)switch to ground. The lift relay coil is energized and the windshield moves (we'll get to that description in a minute). If the operator releases the Window Adjust Switch, the circuit is broken and the coil de-energizes. The motor stops. Similarly, when the cam on the motor encounters the limit, the Up microswitch opens, breaking the circuit. The relay coil de-energizes and the motor stops. The exact same operation happens if the Window Adjust Switch is pressed for DOWN motion. A consequence of the cam design is that at no time are both microswitches open -- there are always at least one switch closed, making contact. The reason for this is once a limit is reached, further energizing of the associated relay coil is prevented and the only complete circuit available for use is through the other relay.

Second the motor control logic description. Battery power is wired to the N/O (pin 87) of each relay through the R/L wire and ground is wired to the N/C (pin 87A) of each relay through the Br wire. The common contact (pin 30) on each relay is wired to one or the other side of the motor (Gr and L wires). In a rest state, each side of the motor is grounded and remains so unless the Window Adjust Switch is pressed. Let's say the operator pushes the Window Adjust Switch for UP motion -- the Lift relay energizes and the relay contact switches battery power (pin 87) to the Gr wire (pin 30). Power travels through the motor windings and continues via the Lower relay contacts to ground (remember the rest state). The motor rotates in the proper direction. When the Window Adjust Switch is released or the associated limit encountered, power is cut to the relay, the contacts drop and power is cut to the motor. Now, if the operator presses the Window Adjust Switch for DOWN motion, the Lower relay is energized and power is switched from the R/L wire (pin 87) to the L wire (pin 30), through the motor and to ground via the lift relay contacts. The motor now reverses direction because the direction of the current flow is reversed. The windshield lowers until the switch is released or the limit encountered.

This description will help to debug wiring problems. For example, to bench test the windshield, apply power directly to the motor in different polarities to see that the motor is functional. Understanding the operation will lead you to understand that at no time can both switches be open; only one is open at any one time when a limit is encountered or both are closed during travel.

Circuit Card Details

The bundle of 6 wires to the right feeds to the windshield motor and limit sensing microswitches on the BMW assembly. The bundle of three wires on the top-left feeds to the momentary switch mounted on the console. Both have been strain relieved with tie-wraps. This card normally would have been wired with the contacts down but I originally had one idea about how I would construct the card yet I altered that idea as the installation progressed. Knowing what I know now, I would recommend installing the relays and wiring on the opposite (correct) side of the board. The board mounts to the frame of the windshield using brass standoffs and 6-32 machine screws. I drilled holes in the frame and tapped the holes with 6-32 thread to accomodate the standoffs.

The circuit that is available on other sites shows both switched and unswitched 12V needs to be fed to the circuit. This is not true. Only 12V switched is required. I obtained my voltage feed from the fuse box. There is a BMW supplied connector called Additional Instruments. This conector has 4 contacts -- +12V switched, Ground, Gas float and Lights. I tapped off +12V and ground and fed it to my circuit.

Window Adjust Switch

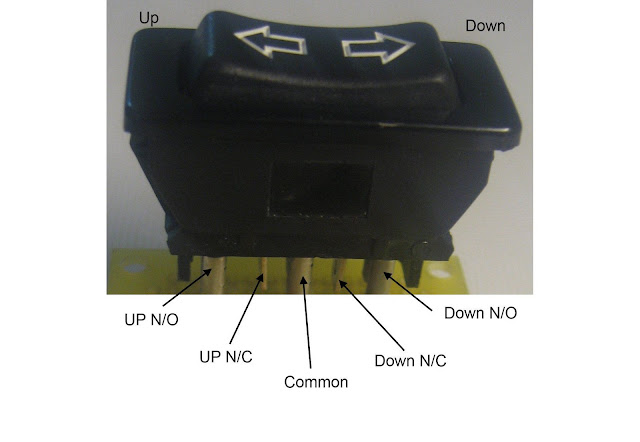

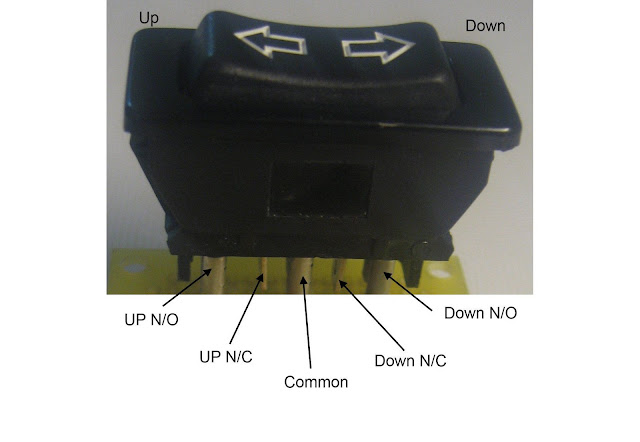

I mounted the UP-DOWN control switch in the dash because it made the unit integral, only needing to remove a single two-prong connector when removing the dash and windshield assembly. This works better than trying to install the switch in the handlebar console near the tank. The switch was a surplus automotive power window switch I picked up at a local surplus dealer. The switches used in the K100 are a standard 17mm x 31mm size, very common in the automotive industry. Most any switch will fit. The switch pinout is shown below:

I connected my circuit to the terminals labelled UP-NO, Common and Down-NO.

I bench tested my circuit before installing onto the motorcycle. I used a 12V 7A power supply to supply power to the circuit. I made voltage and continuity measurements of the relays prior to connecting the motor to make sure that the proper voltages were being supplied. The circuit had problems which I traced to broken spade connectors in the momentary control switch harness. Once repaired, the circuit worked flawlessly.

Instrument Cluster Mounting

Bert pointed out to me that I would need to raise the instrument cluster by 25mm (1") to allow it to clear the dash. This is because the instrument cluster on a K1100 is fixed, not movable as in the K100. I constructed two standoffs by purchasing a 1/8" x 3/4" x 3 foot piece of flat aluminum stock, slicing off four pieces 2" long and gluing pairs together to form 1/4" x 3/4" x 2" standoffs. I drilled two holes; one clearance for an M6 bolt, and the other tapped at M6. I secured the standoffs to the instrument cluster support with M6 bolts:

... and secured the assembly to the triple clamp using the original bolts:

These are pictures of the finished windshield installation:

Thanks for reading.

Mounting an electric windshiel on a K100rt Sat Mar 29, 2008 10:03 pm

Mounting an electric windshiel on a K100rt Sat Mar 29, 2008 10:03 pm

Part #2 is $700 at a BMW dealer

Part #2 is $700 at a BMW dealer

Part #2 is $700 at a BMW dealer

Part #2 is $700 at a BMW dealer

(Thanks Bert; I made some modifications to your original)

(Thanks Bert; I made some modifications to your original)

1986 k75, 1985 K100rt,

1986 k75, 1985 K100rt,