Well, well, well, look at all the trouble I caused!

Looks like you managed together to suss out all out. When my tech friend put K-1100 TBs on my K-100 we simply disassembled the original TB rack, disassembled the K-1100 TB rack, and swapped the K-1100 TBs into the original K-100 TB rack. We kept the stock K-100 injectors. Mathias has enough experience from his time with BMW Research to know this set up does not benefit from using K-1100 injectors. Too much fuel. Instead we make two adjustments to the air flow meter, one to loosen the preload on the vane spring one click or two (have to try each setting and see what works, but two clicks can be too rich sometimes) and to adjust the postion of the potentiometer wiper. This last one is excruciatingly sensitive.

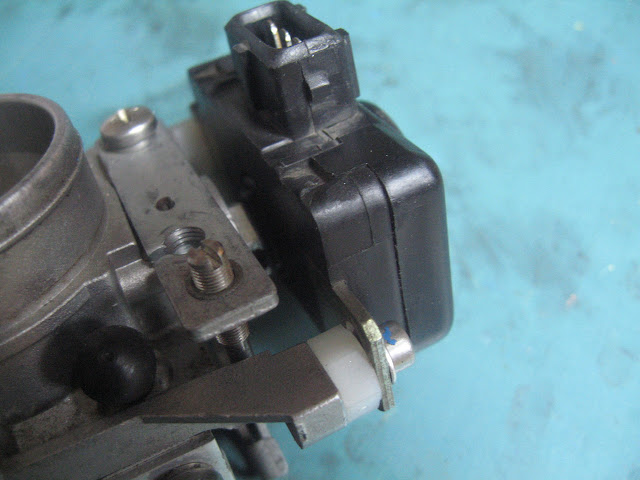

Bravo on figuring out how to attach an L-Jet TPS on the back of a K-1100 TB. I did something similar out of a chunk of aluminum round stock. I discovered on the dyno that if you set the air flow meter bypass screw to give you 2% CO at idle, as soon as you crack the throttle the mixture goes way rich without the TPS. This is why the TPS has an idle enrichement setting. With idle enrichement AND idle CO set at 2%, as you crack the throttle the loss of idle enrichement is compensated for by the tendency of the mixture to spike rich off idle.

On the other end at WOT with no TPS, the mixture tends to go lean. Not dangerously so unless you spend a lot of time at WOT, so it's ok for most bikes in the US to go without a TPS. Eliminating the TPS eliminates the closed throttle fuel cut off above 2000 rpm and this makes off/on throttle transitions smooth, making technical riding on tight mountain road, or riding in the snow much smoother than it is with the TPS functioning. BMW test riders would disconnect the TPS of early K bikes for riding in the snow (R&D guys have big brass ones to ride in the winter in Germany!).

K-1200 TBs have no provision for a fast idle setting, since this is accomplished through the engine management on K-1200s instead of manually as on the K-100 and K-1100. If you do it, you have to be prepared to manually hold the throttle open on cold days until the bike warms sufficiently.

You noticed the four air fittings on the back of the K-1100 TBs. On my bike those are closed off as was done by our members here. You sussed that part out successfully. But here is what was done on my bike. I have all four TB's connected with vacuum hoses to the vacuum ports on each TB using plastic T connectors. Now the fuel pressure regulator receives a steadier vacuum signal than it can if it only reads vacuum off the rear cylinder. This smooths pressure variations in the fuel rail and makes for a bit smoother running. This is subtle stuff, but you can notice the difference. I have a bone stock K100RS, both with the long duration 284 degree cams, and the bike with the K-11 TBs is much smoother. My modified bike makes an honest 72 horses at the rear wheel. Not bad for an otherwise stock engine with a high quality valve job (port matching, 5 angle valve cut, knife edged valve guide bosses)

Now wrap your heads around the next increment. The current project is a used K-1100 engine, drive line and frame. But, my tech friend is yanking the four valve head and replacing it with a two valve head from a K100

The head is ported, combustion chamber shape altered, valve clearance reliefs cut into the piston crowns with a very nice jig a machinest friend of his made, and it will be fitted with 284 degree cams, K-1200 TBs and L-Jetronic. I have ridden the prototype. It makes about 115 horses, enough to lift the front tire easily.

It makes power from 3000 rpm to redline and because the K-1100 bottom end has very short slipper pistons and 7 mm longer rods the engine is buttery smooth. The early head has more coolant in it and tolerates more power than the four valve head. Of couse we will use an early three row radiator.

We are building what will look like a very early K-100RT using 1985 bodywork (scored a complete used RT fairing with all the hardware for $350) and an early K100 wiring harness. No ABS, L-Jetronic, small battery, K100RS 16V footpeg plates, K1100LT front wheel and K1100 RS rear wheel (both 18 inchers), and early Fichtel Sachs K100 fork with the fork bridge built in, R100R Mystic triple clamp (less offset = more trail and no more K weaving and wallowing, but a machinest nightmare to implement ) and custom brackets to hang the K1100 four piston calipers on the stock K1100 rotors (already have something like this on my K100RS). We figure this will be a 565 pound wet weight bike that is going to surprise and awful lot of supposedly better machinery on the back roads. Btw, a first generation GSX/R-1000 conventional front fork bolts on too and works really well.

Ain't I a trouble maker AJ? Heh, heh, heh.

Re: K1100 throttle bodies on a K100 Sun Jan 22, 2012 7:32 pm

Re: K1100 throttle bodies on a K100 Sun Jan 22, 2012 7:32 pm

The head is ported, combustion chamber shape altered, valve clearance reliefs cut into the piston crowns with a very nice jig a machinest friend of his made, and it will be fitted with 284 degree cams, K-1200 TBs and L-Jetronic. I have ridden the prototype. It makes about 115 horses, enough to lift the front tire easily.

The head is ported, combustion chamber shape altered, valve clearance reliefs cut into the piston crowns with a very nice jig a machinest friend of his made, and it will be fitted with 284 degree cams, K-1200 TBs and L-Jetronic. I have ridden the prototype. It makes about 115 horses, enough to lift the front tire easily.

[/url]

[/url] [/url]

[/url]

.

.

[/url]][/url]

[/url]][/url]