1

Broken exhaust manifold Thu Sep 03, 2020 7:28 am

Broken exhaust manifold Thu Sep 03, 2020 7:28 am

Holister

Life time member

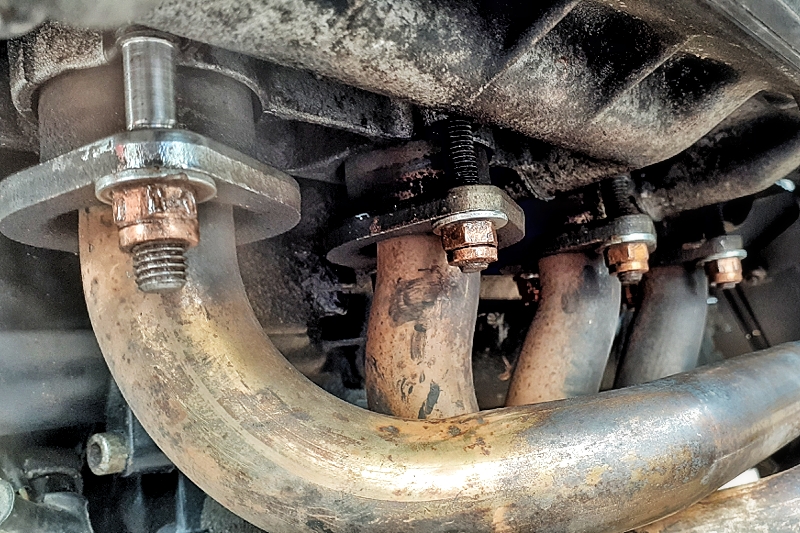

My Sweet Thing K1100RS has been trouble free since I bought her in early 2016 but recently after a 10,000km tour of Vic, Tassie and southern NSW I've found that the very front exhaust stud has fallen out.

Inspection reveals that the previous owner had stripped the stud hole in the head and installed a Helicoil. In doing so the head around the stud hole has cracked and he's glued it back together with epoxy. It's a mess. The helicoil is partly exposed and of course the stud just won't tighten up at all.

I've had an automotive engineer inspect it and he says he can build it back up with alloy weld but I need to take the head off for him to do that properly. That's ok, no problem there, but he's also suggested that I'd be better just to repair it with JB Weld. It's certainly a much quicker and cheaper solution.

I've had a look at the specs on JB Weld. Two products might be suitable.

JB Weld Original Cold Weld Epoxy - 3,000psi up to 250ºc Data sheet here

JB Weld ExtremeHeat - 500psi up to 1,300ºc

So the idea will be to get the old helicoil out.

Roughen all the surfaces. Clean it up and degrease.

Fill the stud hole and surrounding area with JB Weld epoxy.

Re-drill and tap.

Wondering if anyone has had any experience doing this? Is it going to work? There's a large amount of tensile force on a stud and the heat will be quite high.

I'd like to use the JB Original Cold Weld because it appears to have the greater strength but only rated to 250ºc. The exhaust would probably get a lot hotter than that but maybe not the alloy.

Any thoughts and suggestions before I attack this would be very welcome.

Cheers

Inspection reveals that the previous owner had stripped the stud hole in the head and installed a Helicoil. In doing so the head around the stud hole has cracked and he's glued it back together with epoxy. It's a mess. The helicoil is partly exposed and of course the stud just won't tighten up at all.

I've had an automotive engineer inspect it and he says he can build it back up with alloy weld but I need to take the head off for him to do that properly. That's ok, no problem there, but he's also suggested that I'd be better just to repair it with JB Weld. It's certainly a much quicker and cheaper solution.

I've had a look at the specs on JB Weld. Two products might be suitable.

JB Weld Original Cold Weld Epoxy - 3,000psi up to 250ºc Data sheet here

JB Weld ExtremeHeat - 500psi up to 1,300ºc

So the idea will be to get the old helicoil out.

Roughen all the surfaces. Clean it up and degrease.

Fill the stud hole and surrounding area with JB Weld epoxy.

Re-drill and tap.

Wondering if anyone has had any experience doing this? Is it going to work? There's a large amount of tensile force on a stud and the heat will be quite high.

I'd like to use the JB Original Cold Weld because it appears to have the greater strength but only rated to 250ºc. The exhaust would probably get a lot hotter than that but maybe not the alloy.

Any thoughts and suggestions before I attack this would be very welcome.

Cheers

__________________________________________________

1989 K100RT VIN 0097367 (naked) 1996 K1100RS VIN 0451808 |  | Fuel: 95 Octane Engine Oil: Nulon Full Synthetic 15W50 Gear Box Oil: Nulon Synthetic 75W90 |

K1 Black 1993 60K Km

K1 Black 1993 60K Km