1

Milling some new inlet manifolds Tue Aug 13, 2019 3:47 pm

Milling some new inlet manifolds Tue Aug 13, 2019 3:47 pm

Tommy2305

Silver member

Since my Inlet manifold is leaking, I plan on milling som new ones out of billet aluminium with silicone hose, because why not

Does anyone know if it is going to affect the engine in a bad way, that the internal angel/contour is made differently?

I can only think that it will optimize flow, but maybe that will result in a lean mixture somehow?

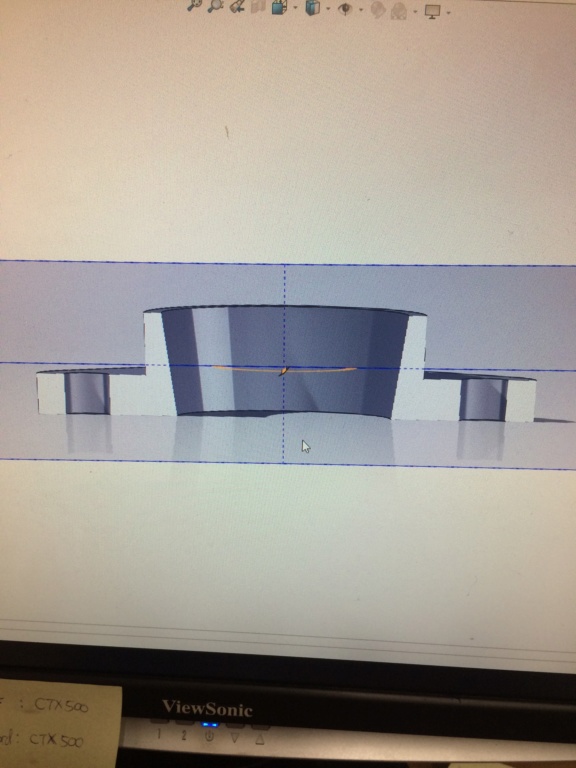

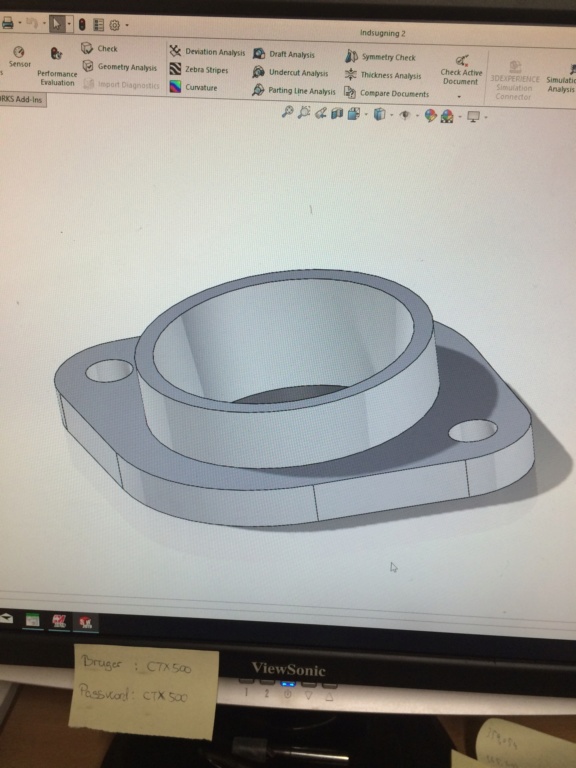

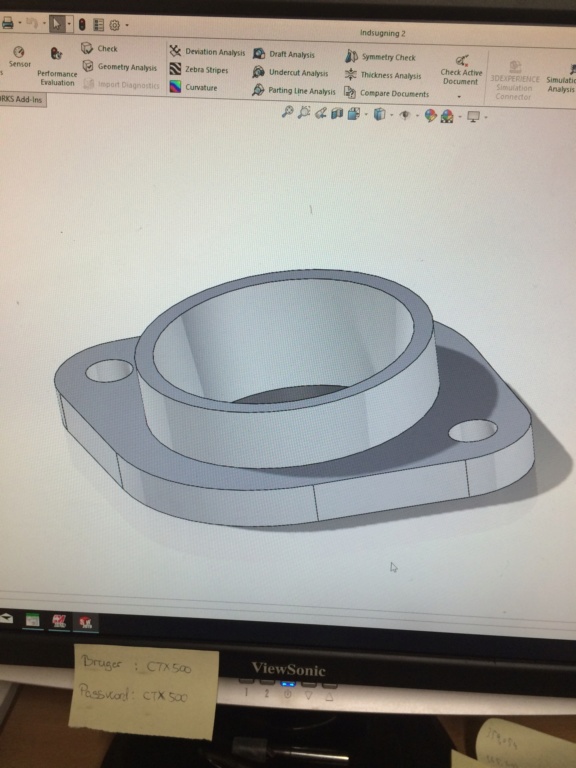

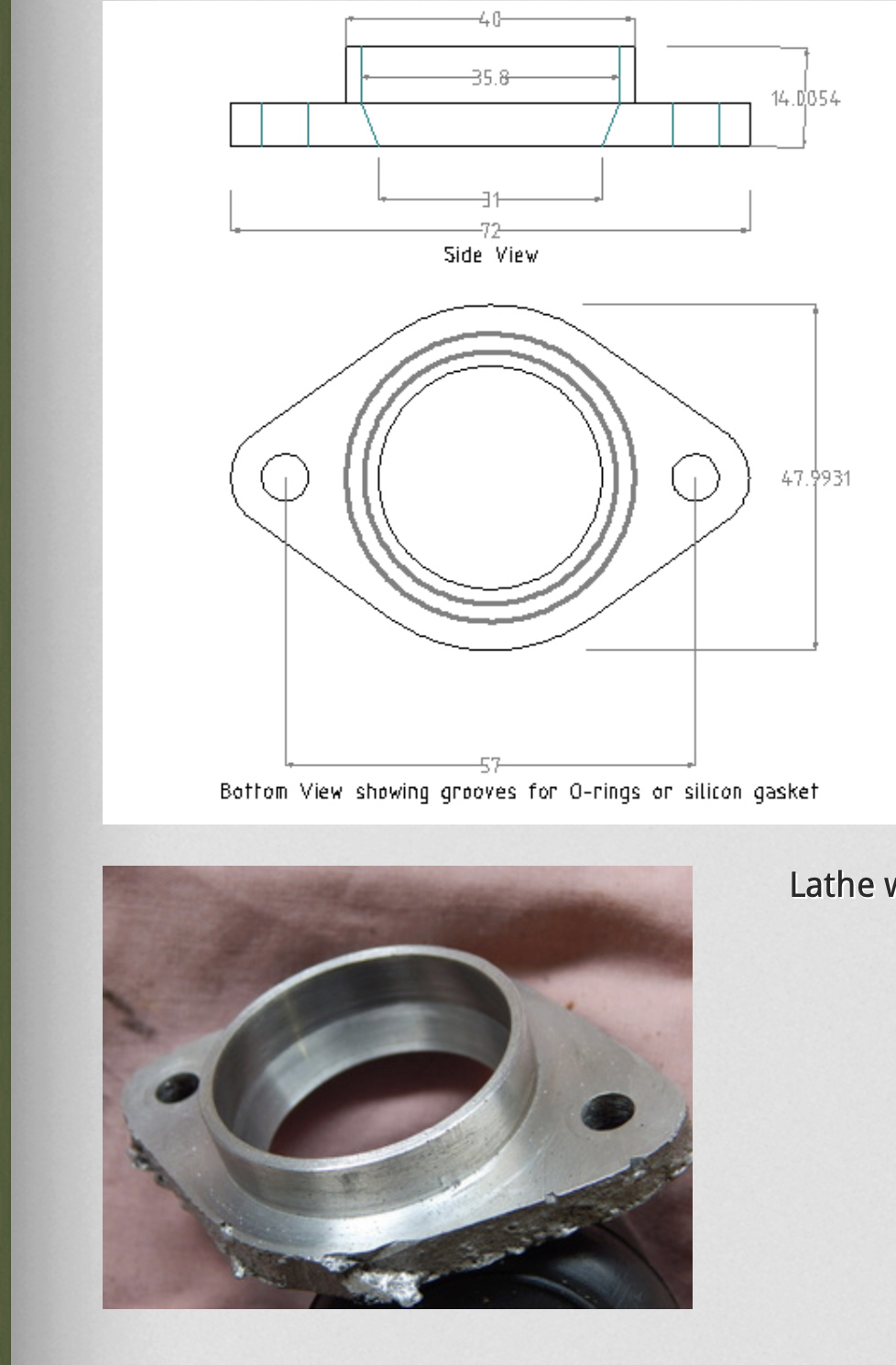

The 3D drawing is my idea, compared to the 2D drawing which should be more or less like the original.

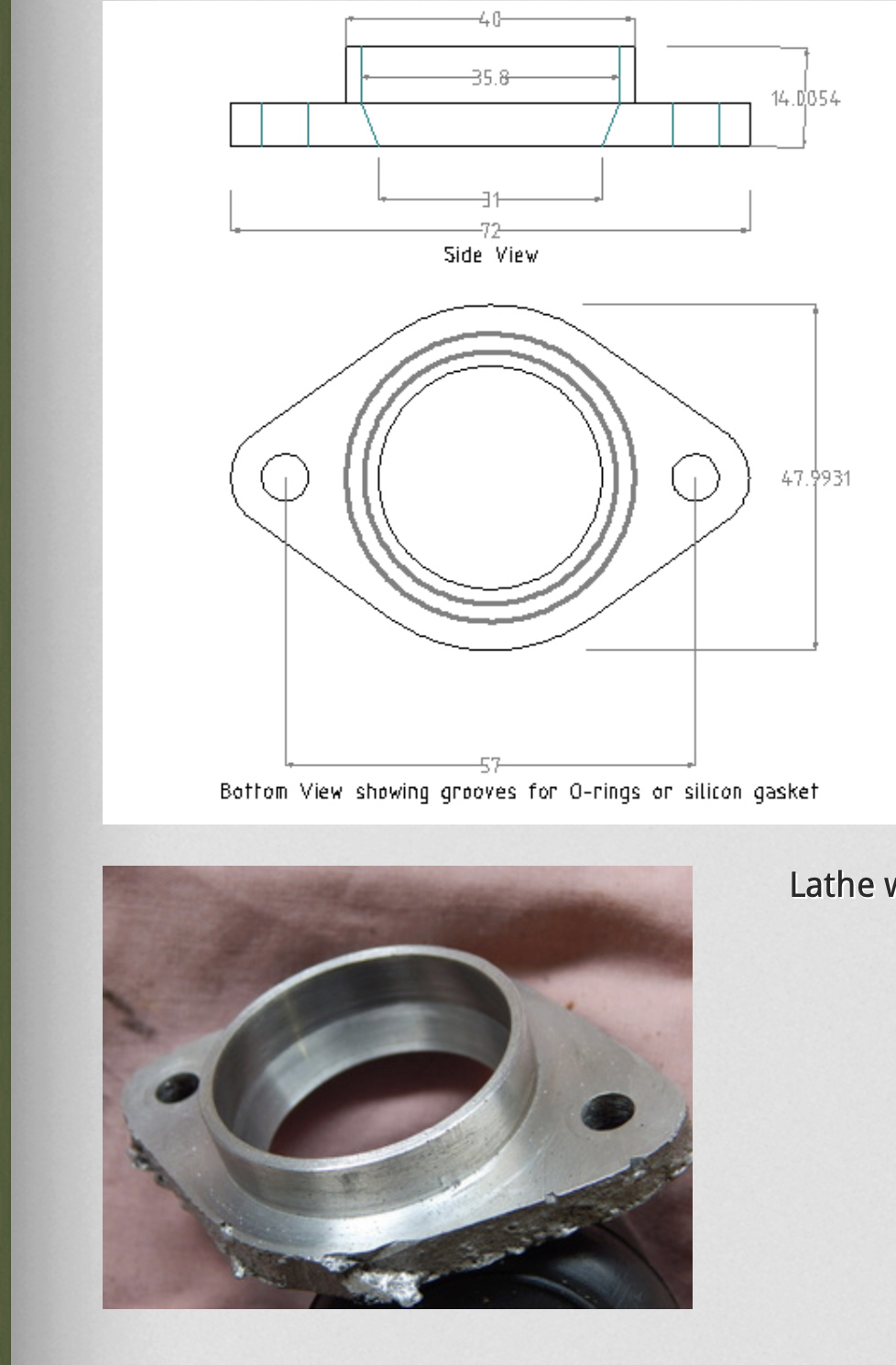

The whole idea came from this guy who casted his own at home and I really liked the idea

https://bmwk100k75.weebly.com/air-leaks.html

Close up pictures of an inlet manifold from different angles would really be appreciated! Even an old knackered one

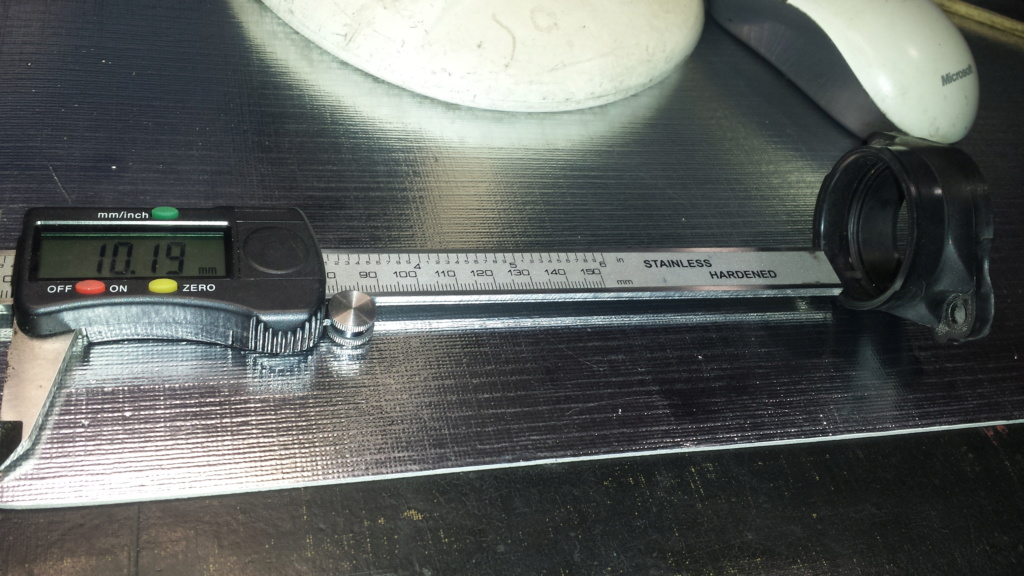

And at last, can anyone confirm the measurements on the last picture?

Does anyone know if it is going to affect the engine in a bad way, that the internal angel/contour is made differently?

I can only think that it will optimize flow, but maybe that will result in a lean mixture somehow?

The 3D drawing is my idea, compared to the 2D drawing which should be more or less like the original.

The whole idea came from this guy who casted his own at home and I really liked the idea

https://bmwk100k75.weebly.com/air-leaks.html

Close up pictures of an inlet manifold from different angles would really be appreciated! Even an old knackered one

And at last, can anyone confirm the measurements on the last picture?

[url=https://servimg.com/view/20089755/21]

[url=https://servimg.com/view/20089755/21]

[url=https://servimg.com/view/20089755/24]

[url=https://servimg.com/view/20089755/24]