1

advice needed with cam cover broken thread Sat May 26, 2018 9:58 am

advice needed with cam cover broken thread Sat May 26, 2018 9:58 am

audibob

Life time member

HI all.

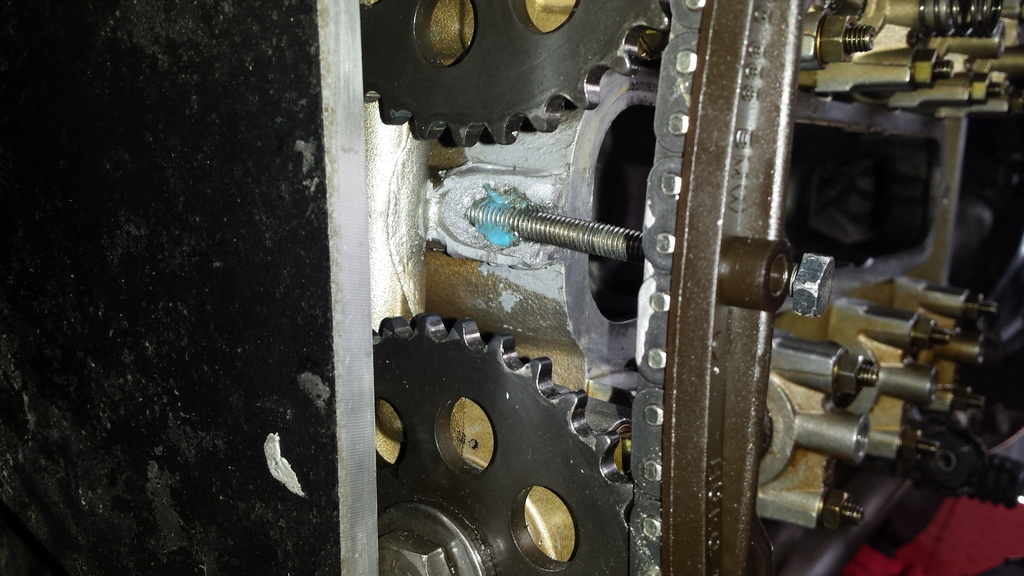

just refitted cam cover after fitting a k75 tensioner

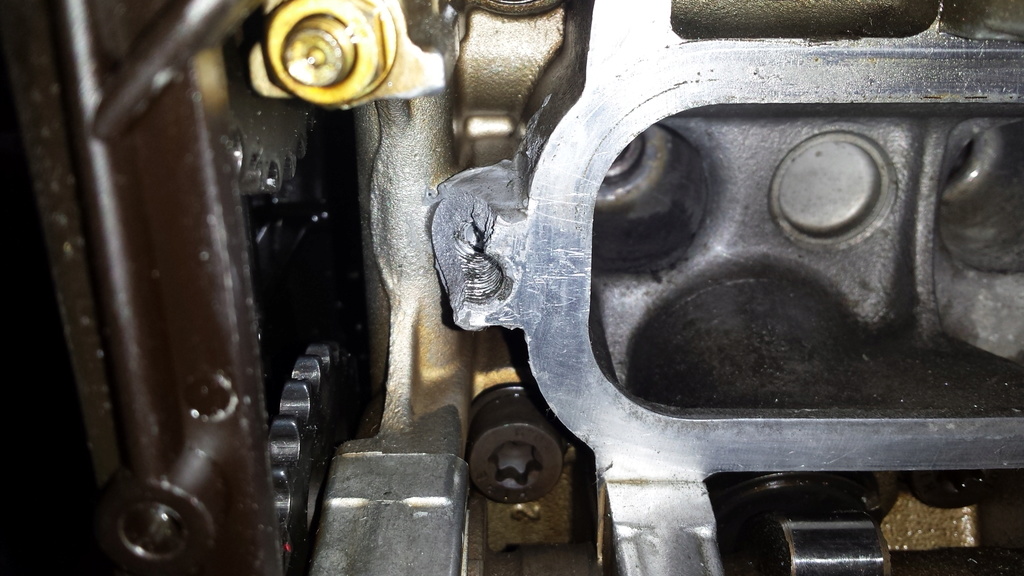

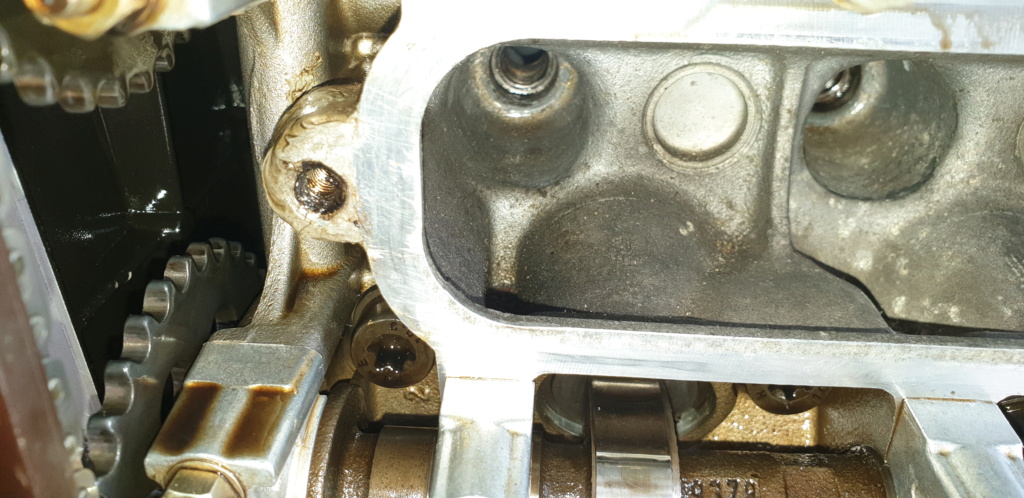

on my k100 and somehow the left middle cam cover bolt thread casting broke off

Has anyone had this happen, and apart from a different head, how did they overcome this.

There might be enough metal in the casting to drill past the end of the thread and use a longer bolt.

or has anyone blanked the hole in the cam cover to stop oil leakage, and just relied on the other bolts to seal the cover

I do not want to fit a different head on my bike

So I need some advice guys

Possibly a mobile ally welder ?

Thanks on advance

bob

just refitted cam cover after fitting a k75 tensioner

on my k100 and somehow the left middle cam cover bolt thread casting broke off

Has anyone had this happen, and apart from a different head, how did they overcome this.

There might be enough metal in the casting to drill past the end of the thread and use a longer bolt.

or has anyone blanked the hole in the cam cover to stop oil leakage, and just relied on the other bolts to seal the cover

I do not want to fit a different head on my bike

So I need some advice guys

Possibly a mobile ally welder ?

Thanks on advance

bob

__________________________________________________

Yamaha 90

Honda CD 175

Honda CB 360

Triumph T 140V Bonneville

Triumph T150 Trident

Honda CB750 F1

Cz 175

Yamaha XS 750

R 100/7

R 80

K100 LT

K100 LT current bike