1

Repairing hole in water/oil pump body Sat Jan 27, 2018 5:10 am

Repairing hole in water/oil pump body Sat Jan 27, 2018 5:10 am

MikeyD

active member

I've done a lot of reading through here for my pump service and other items. I appreciate all the helpful information. Regardless I managed to make a wrong turn. I'm always surprised at some of the things I do after 35 years of working on mechanical stuff.

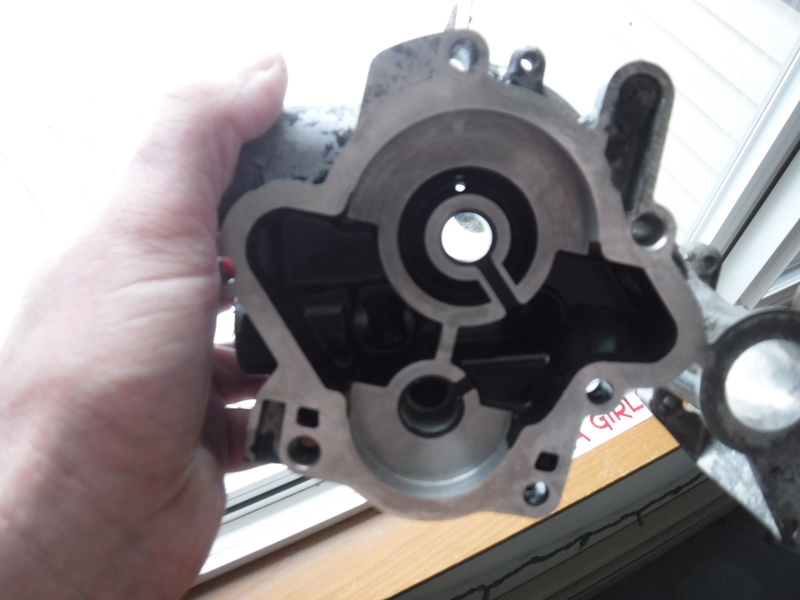

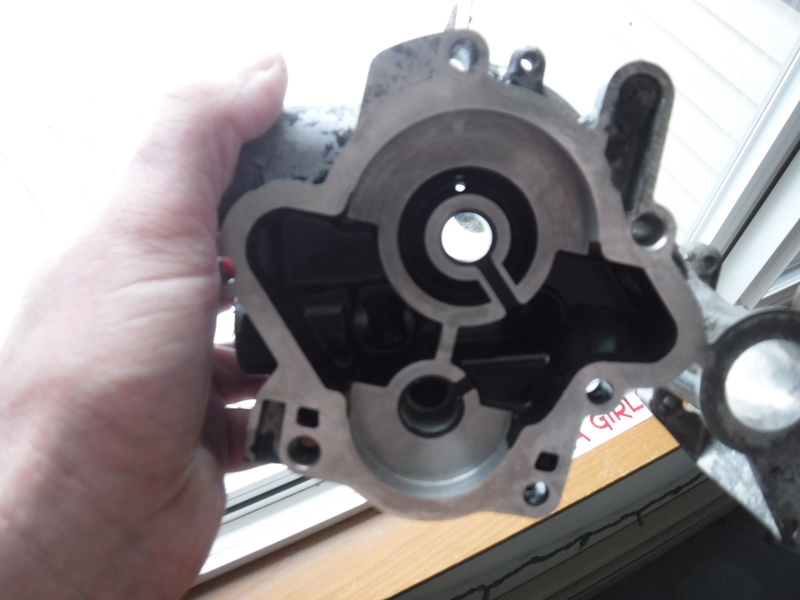

I think I may have botched the water pump job in a way no one else has before. On my 1985 K100RT I was trying to get the last, deepest seal out of the front of the pump body and was not having much luck. I thought I detected some space behind the metal portion of the old seal so I decided to drill a hole in it and tap it with my slide hammer like I have done with other difficult-to-remove seals. There was no space under the seal. Unfortunately I stupidly drilled right through to the other side of the pump body. Looking at the first photo, in the front of the pump where the seals go you'll notice two holes where there should be one. The bottom photo shows where the hole comes through the back side of the pump.

Looking at the first photo, in the front of the pump where the seals go you'll notice two holes where there should be one. The bottom photo shows where the hole comes through the back side of the pump.

I figure I have 3 options now.

1.) I can pitch the whole pump body and buy a new or used pump body.

2.) Repair the whole with two part epoxy for metal, something like JB Weld (https://www.jbweld.com/collections/epoxy-putty-sticks/products/steelstik-epoxy-putty-stick).

3.) Repair the whole with dura-fix (http://durafix.com/index.html), which is like an aluminum braze.

With #3, I have to heat the aluminum to 735 degrees F and I'm concerned I may warp the sealing surfaces of the pump body.

With #2 I'm concerned that the little patch will fail and introduce an engine damaging piece of hardened epoxy into the oil stream.

Any thoughts? Lately I'm leaning toward the JB Weld.

It may have been a case of "don't fix it if it ain't broke". I didn't have any coolant leak, but old, leaky oil was caked on really thickly. I figured the mating surfaces were leaking. I have the bike torn down for a lot of other work so I wanted to address the leak. As it turned out, the threaded stud at the front end of the drive gear was mostly sheared but barely hanging on to secure the water pump impeller. I know I didn't shear it while removing it because I barely turned the nut and it came off. Plus, the the sheared metal was corroded like it had been exposed for a long time. The last photo shows that. Has anyone encountered that before?

I think I may have botched the water pump job in a way no one else has before. On my 1985 K100RT I was trying to get the last, deepest seal out of the front of the pump body and was not having much luck. I thought I detected some space behind the metal portion of the old seal so I decided to drill a hole in it and tap it with my slide hammer like I have done with other difficult-to-remove seals. There was no space under the seal. Unfortunately I stupidly drilled right through to the other side of the pump body.

Looking at the first photo, in the front of the pump where the seals go you'll notice two holes where there should be one. The bottom photo shows where the hole comes through the back side of the pump.

Looking at the first photo, in the front of the pump where the seals go you'll notice two holes where there should be one. The bottom photo shows where the hole comes through the back side of the pump.I figure I have 3 options now.

1.) I can pitch the whole pump body and buy a new or used pump body.

2.) Repair the whole with two part epoxy for metal, something like JB Weld (https://www.jbweld.com/collections/epoxy-putty-sticks/products/steelstik-epoxy-putty-stick).

3.) Repair the whole with dura-fix (http://durafix.com/index.html), which is like an aluminum braze.

With #3, I have to heat the aluminum to 735 degrees F and I'm concerned I may warp the sealing surfaces of the pump body.

With #2 I'm concerned that the little patch will fail and introduce an engine damaging piece of hardened epoxy into the oil stream.

Any thoughts? Lately I'm leaning toward the JB Weld.

It may have been a case of "don't fix it if it ain't broke". I didn't have any coolant leak, but old, leaky oil was caked on really thickly. I figured the mating surfaces were leaking. I have the bike torn down for a lot of other work so I wanted to address the leak. As it turned out, the threaded stud at the front end of the drive gear was mostly sheared but barely hanging on to secure the water pump impeller. I know I didn't shear it while removing it because I barely turned the nut and it came off. Plus, the the sheared metal was corroded like it had been exposed for a long time. The last photo shows that. Has anyone encountered that before?

__________________________________________________

1985 K100RT (0052390), 1985 K100 (0030066), 2003 K1200GT (ZK01448), 1984 R65, 1984 R80ST, 1974 R90/6, 1976 R90/6, 1997 R850R, 1991 Honda CB250, 1998 Sportster 883