1

Help save this endangered species-'84 petrol tank wanted. Fri Oct 28, 2016 7:14 pm

Help save this endangered species-'84 petrol tank wanted. Fri Oct 28, 2016 7:14 pm

Motorbike Mike

Life time member

OK guys, I'm after some help for quite a rare bike I think.

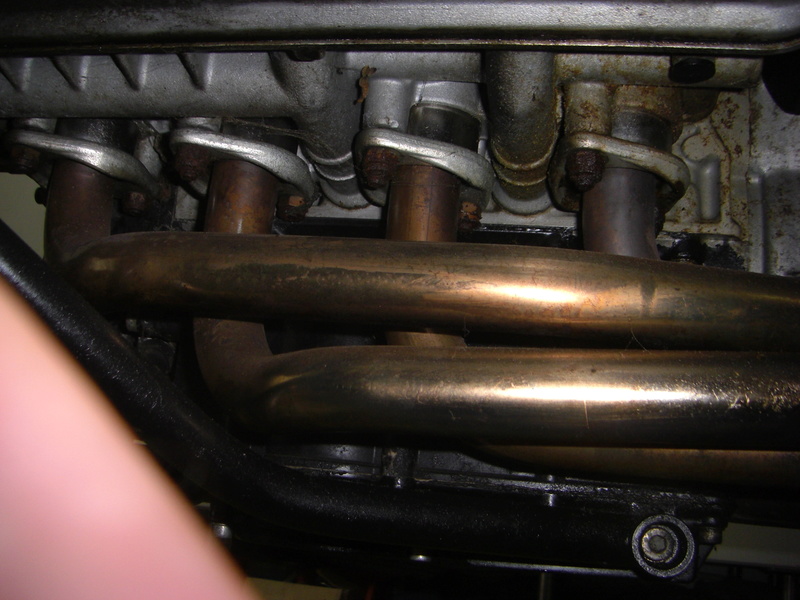

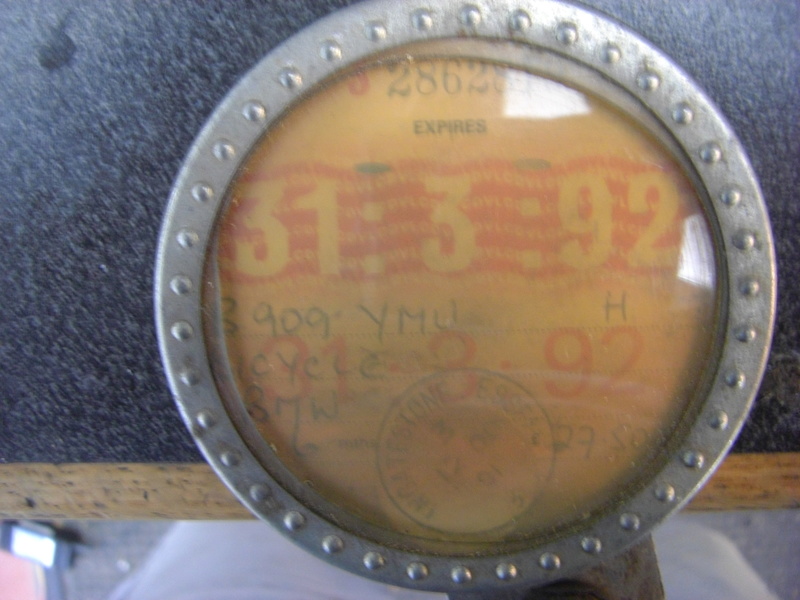

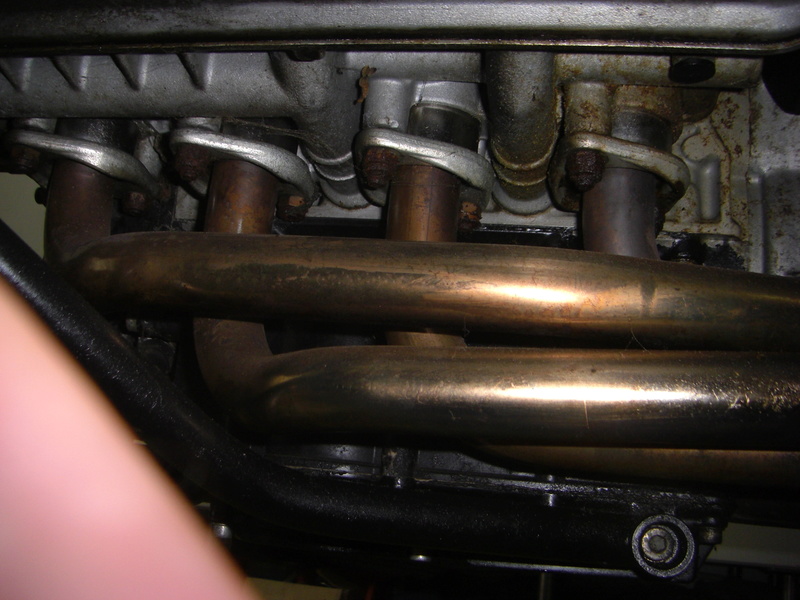

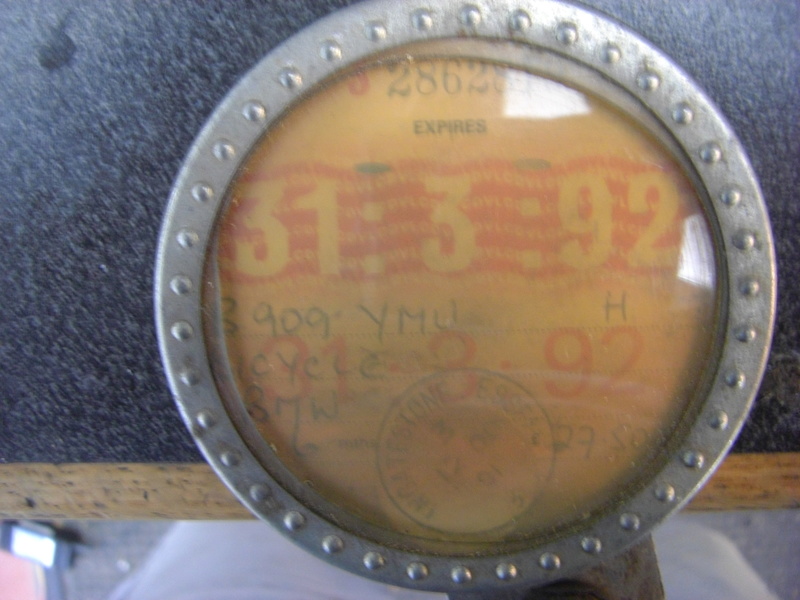

It's a 1984 K100 Basic that I rescued from a chap that owned the K for some years but didn't know what he had or how best to look after it. It never even made it back to the dealer to have the rear disc replaced under warranty for the later solid version! The bike was a non runner (last on the road in '92) when I bought it but was soon running again with fresh fuel and a good battery. I built it back up and rode it for a while last year-it's a real flier! I believe that the mileage is genuine when you look at the factory paint on the bolt heads and the underside of the motor.

It's a bike to be kept original, NOT to be chopped up into a Cafe Racer so here's where my issues begin. As 99% of us know the K's have an Achilles heel, the petrol tank. It's corroded through under the fuel pump which isn't a problem for me as I can weld aluminium but, if I repair the tank I'll have to paint it and if I do that I'll have to paint the rest of the bodywork to make it all match and as I said, I don't want to restore the bike.

I need an early K tank in Polaris silver (576) with the fuel level sensor at the front left, in nice condition, a pair of side panel too if possible. Does anyone have a tank that they'd part with? I'll pay the asking price and shipping costs.

Thanks in advance.

It's a 1984 K100 Basic that I rescued from a chap that owned the K for some years but didn't know what he had or how best to look after it. It never even made it back to the dealer to have the rear disc replaced under warranty for the later solid version! The bike was a non runner (last on the road in '92) when I bought it but was soon running again with fresh fuel and a good battery. I built it back up and rode it for a while last year-it's a real flier! I believe that the mileage is genuine when you look at the factory paint on the bolt heads and the underside of the motor.

It's a bike to be kept original, NOT to be chopped up into a Cafe Racer so here's where my issues begin. As 99% of us know the K's have an Achilles heel, the petrol tank. It's corroded through under the fuel pump which isn't a problem for me as I can weld aluminium but, if I repair the tank I'll have to paint it and if I do that I'll have to paint the rest of the bodywork to make it all match and as I said, I don't want to restore the bike.

I need an early K tank in Polaris silver (576) with the fuel level sensor at the front left, in nice condition, a pair of side panel too if possible. Does anyone have a tank that they'd part with? I'll pay the asking price and shipping costs.

Thanks in advance.