1

Too-Fast Idle, TB linkages & What-Worked-For-Me Wed Jan 04, 2017 12:30 pm

Too-Fast Idle, TB linkages & What-Worked-For-Me Wed Jan 04, 2017 12:30 pm

Kafflut

Silver member

My motor now idles nicely at below 1000 rpm and at ± 1200 when warm. No more 1700 rpm that cannot be adjusted down.

From the beginning I suspected that the too-fast idle was caused by the throttle valves not closing properly. The accelerator & fast idle cables were disconnected, TPS removed – all the common reasons for not closing had been eliminated. Adjusting the between-TB linkages while running the engine did not fix this - although the TBs were in sync it seemed that they were still not closing.

I removed the TB assembly. I adjusted the linkage between TB3 & TB4 so TB3 was in its most open position relative to TB4. I repeated this for the other linkages, TB2 open relative to TB3 and TB1 open relative to TB2. In effect TB4 valve was now shut and the others in varying degrees of open.

Using a strip of audio magnetic tape as a "feeler gauge" I adjusted the center stop screw so TB4 throttle valve was just closed – a distinct drag on the tape/”feeler gauge”. Leaving the stop screw in that position I adjusted the 3 linkages so TB3, TB2 and TB1 butterfly valves offered the same resistance to pulling the "feeler gauge" out as TB4.

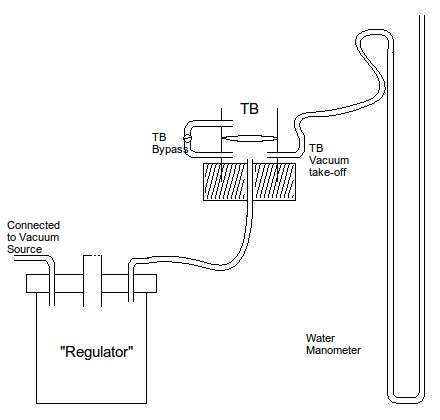

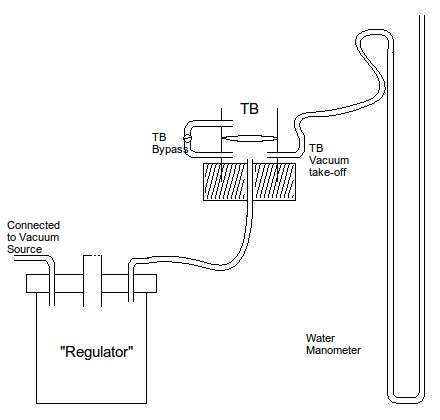

The throttle valves were now physically synced as good as I could get them. In order to fine tune this static sync at the closed position I cobbled together a tester, a process to test the “vacuum” each throttle valve can hold against the same negative pressure applied. The sketch below illustrates the principle.

My vacuum source was the input end of my compressor. With the other tube from the “regulator” connected directly to my water manometer I drilled small holes in the lid of the jar until the manometer showed a difference of about 1.2 meter against atmospheric pressure.

Connecting the TB as shown in the sketch and with the bypass screw shut I could test each TB “vacuum” It took me about 4 iterations of making inter-TB linkage adjustments and they were balanced. Readings on the manometer were between 215mm and 225mm.

After installing the TB assembly I did final adjustments of the bypass screws(using another water manometer) with the engine running. They are balanced and the motor idles below 1000 rpm.

I'll show photos of the actual process in subsequent posts

From the beginning I suspected that the too-fast idle was caused by the throttle valves not closing properly. The accelerator & fast idle cables were disconnected, TPS removed – all the common reasons for not closing had been eliminated. Adjusting the between-TB linkages while running the engine did not fix this - although the TBs were in sync it seemed that they were still not closing.

I removed the TB assembly. I adjusted the linkage between TB3 & TB4 so TB3 was in its most open position relative to TB4. I repeated this for the other linkages, TB2 open relative to TB3 and TB1 open relative to TB2. In effect TB4 valve was now shut and the others in varying degrees of open.

Using a strip of audio magnetic tape as a "feeler gauge" I adjusted the center stop screw so TB4 throttle valve was just closed – a distinct drag on the tape/”feeler gauge”. Leaving the stop screw in that position I adjusted the 3 linkages so TB3, TB2 and TB1 butterfly valves offered the same resistance to pulling the "feeler gauge" out as TB4.

The throttle valves were now physically synced as good as I could get them. In order to fine tune this static sync at the closed position I cobbled together a tester, a process to test the “vacuum” each throttle valve can hold against the same negative pressure applied. The sketch below illustrates the principle.

My vacuum source was the input end of my compressor. With the other tube from the “regulator” connected directly to my water manometer I drilled small holes in the lid of the jar until the manometer showed a difference of about 1.2 meter against atmospheric pressure.

Connecting the TB as shown in the sketch and with the bypass screw shut I could test each TB “vacuum” It took me about 4 iterations of making inter-TB linkage adjustments and they were balanced. Readings on the manometer were between 215mm and 225mm.

After installing the TB assembly I did final adjustments of the bypass screws(using another water manometer) with the engine running. They are balanced and the motor idles below 1000 rpm.

I'll show photos of the actual process in subsequent posts