1

Repair to radiator fairing. Wed Apr 01, 2015 4:03 pm

Repair to radiator fairing. Wed Apr 01, 2015 4:03 pm

sidecar paul

Life time member

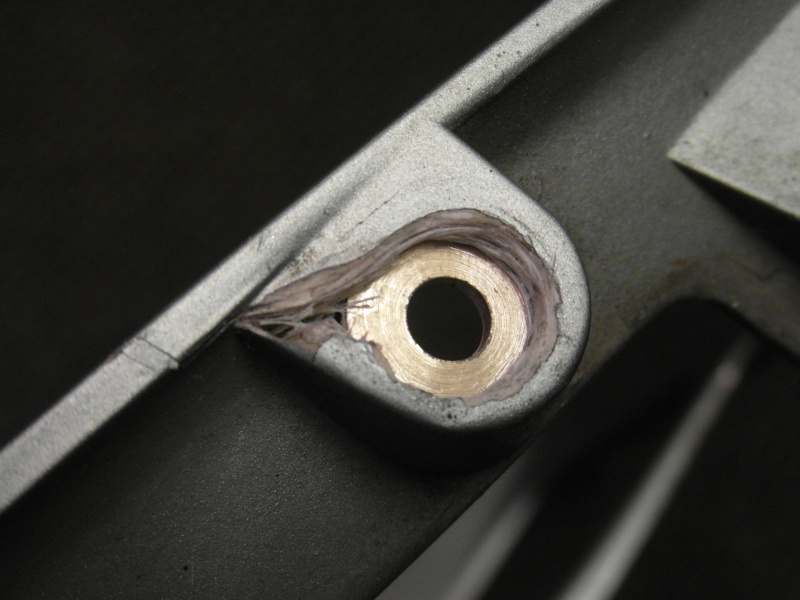

It's fairly common for the screws that hold the radiator fairing to the side panels, to pull through the rad fairing.

When reassembling my solo recently two screws pulled through and I couldn't get the panels to mate properly, so I bought an e-bay panel for £10, suitable for re-painting, but of course, it also had damaged holes. At least I now had a spare panel to try out ideas.

The standard holes are 7mm diameter to take 5mm screws, and as the 5mm screw heads are 10mm diameter, it doesn't leave much surface area to hold things in place. However, there always seems to be a narrow ledge left in the bottom of the recess after the screw has pulled through.

and as the 5mm screw heads are 10mm diameter, it doesn't leave much surface area to hold things in place. However, there always seems to be a narrow ledge left in the bottom of the recess after the screw has pulled through.

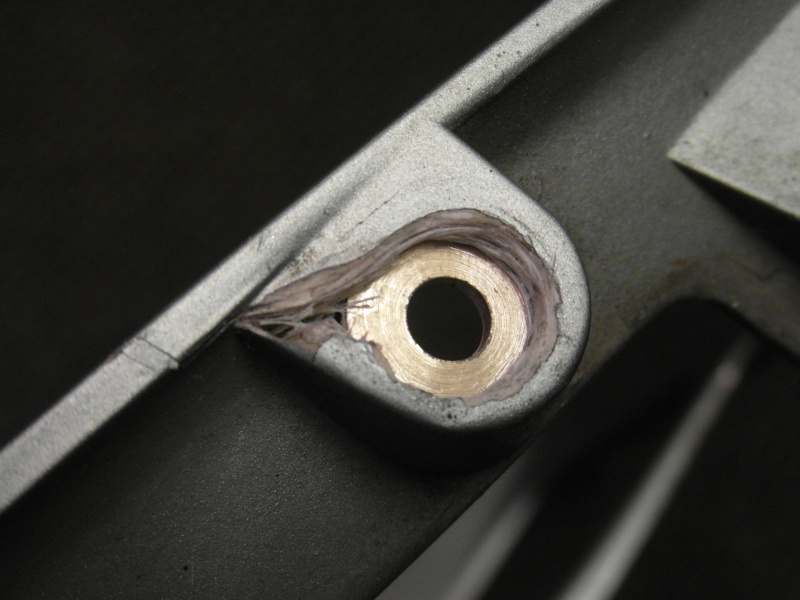

The recesses in the fairing panel are 12mm diameter at the outside with a 1° or 2° taper for the moulding process, so I turned a set of washers,

12mm OD x 5.5mm ID x 1.5mm thick.

These were then pulled into the recesses using a nut, Allen screw and penny washer.

They broach their way into the bottom of the recess and come to rest, tightly on the ledge.

Note that those cracks were there before I pulled my washers into place. (See first picture.)

Even badly damaged holes come good.

I know these sort of repairs need a lathe, but, honestly, it's only a 10 minute job if you have 'a mate with a lathe'.

BTW, the solo's fairing is now fixed by this method, so I'll re-paint the e-bay panel at my leisure.

Paul.

When reassembling my solo recently two screws pulled through and I couldn't get the panels to mate properly, so I bought an e-bay panel for £10, suitable for re-painting, but of course, it also had damaged holes. At least I now had a spare panel to try out ideas.

The standard holes are 7mm diameter to take 5mm screws,

The recesses in the fairing panel are 12mm diameter at the outside with a 1° or 2° taper for the moulding process, so I turned a set of washers,

12mm OD x 5.5mm ID x 1.5mm thick.

These were then pulled into the recesses using a nut, Allen screw and penny washer.

They broach their way into the bottom of the recess and come to rest, tightly on the ledge.

Note that those cracks were there before I pulled my washers into place. (See first picture.)

Even badly damaged holes come good.

I know these sort of repairs need a lathe, but, honestly, it's only a 10 minute job if you have 'a mate with a lathe'.

BTW, the solo's fairing is now fixed by this method, so I'll re-paint the e-bay panel at my leisure.

Paul.

__________________________________________________

'84 K100RS (0014643) (owned since '85), 86 K100RS (0018891) with Martello sidecar (built as an outfit in '88),

'51 Vincent (since '67),'72 Montesa Cota (from new), '87 Honda RS125R NF4 (bought 2015)

....No CARS never ever!