1

1990 K75S 'Spruce-Up' Wed Feb 06, 2013 6:06 pm

1990 K75S 'Spruce-Up' Wed Feb 06, 2013 6:06 pm

MikeP

Life time member

This will be the second K75S treated to a spruce-up in six months, the third K75 I've done and the fourth K-Series attacked in a similar manner in the past twelve months.

As you may have worked out, I have nothing better to do with my time and something approaching a fetish for K-Series 'Bricks' (as well as an almost anal approach so I'm told).

The background is this: My nephew, like me, had an R1150GSA but one thing or another has prevented him using it in the way he intended, ie long journeys loaded to the gunwales. I persuaded him that he should sell the GSA and buy something that he can use on the odd occasion that he gets, something inexpensive yet will provide some pride in owning as well being practical.

In short I suggested a K-Series and as he liked the K75S that I'd owned for a short period last year, why not one for himself knowing that I'd enjoy fettling it for him?

Well in December he did a deal on one, a 16,000 mile bike that was in a sad state cosmetically yet mechanically sound. The price was on the low side, accurately reflecting the condition.

It was subsequently delivered to me just after Christmas. My first task was to take it out and make certain that everything worked, plus to evaluate what needed sorting apart from the obvious. My rides showed that it was all fine except that the steering head adjustment was on the tight side of acceptable.

Only once I'd given the bike a wash did realise how poor it was beneath the mud and dirt. In fact, I discovered that someone had taken a can of black paint and squirted it about with gay abandon covering the dirt on the transmission as well as anything else that got in the way such as the air-box and intake tube (among many things).

After some digging, I think that I've worked out that this bike was laid-up in less than than ideal circumstances. Probably a farm or at least a very rural environment where it had been allowed to stand covered in dirt, probably in a puddle of mud judging by the state of the main-stand:

There wasn't one body panel that didn't have damage to the paint. It was always anticipated that some panels would need re-painting but it was a bit of a blow to discover that they all did. One good thing about this is that it makes a colour change an option. If the whole thing needs re-spraying then why not choose a colour that you like? We've chosen a BMW colour that was used for the K75S but one that I don't think was used for UK bikes.

An hour or two saw the panels all removed, stripped of all the fixings and badges and cleaned inside and out:

Another pile saw the parts for refurbishment begin to grow:

It wasn't all plane sailing however. The long screw that passes through the fork brace and holds the two part mudguard together had suffered badly.

I had anticipated this along with the likelihood that the fork leg mudguard retaining screws would also be seized. A couple of days soaking in penetrating oil worked for two screws but the rest were solid.

The fork brace screw began to turn but once the corroded threads reached the captive nut it was game over. Anyone having experienced this will know that access to the screw and the nut is a problem. My first attempt was to clamp the captive screw that was no longer captive (being captive in a plastic housing is probably like being in an open prison);

It failed and I had to drill it out from the rear.

Next, two of the side screws were solid (both on the same side and the side of the bike that seems to have suffered most from the elements, possibly because it was up against a wall with one side a bit better protected). With the forks removed, I set about driling out the screws:

I've had to do this before now and find that leaving the head of the Allen screw in place, it acts as a guide for the drill. Once beyond the depth of the head I cut the head off.

It's always a bit of a leap of faith to drill by hand (not a bench drill) into a steel screw that's housed in soft aluminium. The only saving grace here is that if you end up damaging the ali at least here it's not threaded and nor is the size of the hole crucial. As it is, I use an under-size drill bit then pick out the remains of the screw.

Having done this sort of thing on cars and bikes for many years, I've learnt that my best modus operandi is to clean, polish and refurbish parts as I remove them. That way there's less tendency to get all excited about putting it back together and being tempted to rush things or cut corners. It does make re-assembly quicker and there's a real pleasure to had from taking a component from the shelf that's all sorted when re-assembly begins. It's the nearest I'll ever get to building something new.

So, the forks were stripped, cleaned and the sliders repainted:

The same goes for the smaller parts such as the battery strap screws, the rear mudguard retaining straps and the seat hinge plates:

Removing the paint from the intake tube:

Cleaning the hoses and clips etc;

Done:

I have a pet theory that much of the problems associated with water in the fuel tanks of these bikes is caused by the oxidisation that builds up under the filler and breaks the seal:

It afflicts the seal on the flap too:

It's just a matter of scraping the white crusty muck off, then a dob of rubber treatment helps the seals remain flexible:

The matt finish always discolours from polish. A wipe with acetone or even brake cleaner is enough to return it to as new:

The tight steering was explained by an over-tightened adjuster. The bearings were just starting to show signs of brinelling. They're too cheap to ignore so it's off with them:

The bare aluminium fork clamps had suffered the usual oxidisation and the screws the usual steel into ali, add moisture and you get cement issues. The threads were cleaned with a tap:

Then the fork clamp given a quick spin with an emery wheel:

And finally the whole thing gets a quick buff-up with steel wool and Solvol metal polish:

The upper clamp gets the same treatment, before:

After:

The box of cleaned or refurbished parts grows:

More washing, scrubbing and polishing done:

The radiator was flushed through, cleaned and the fan tested:

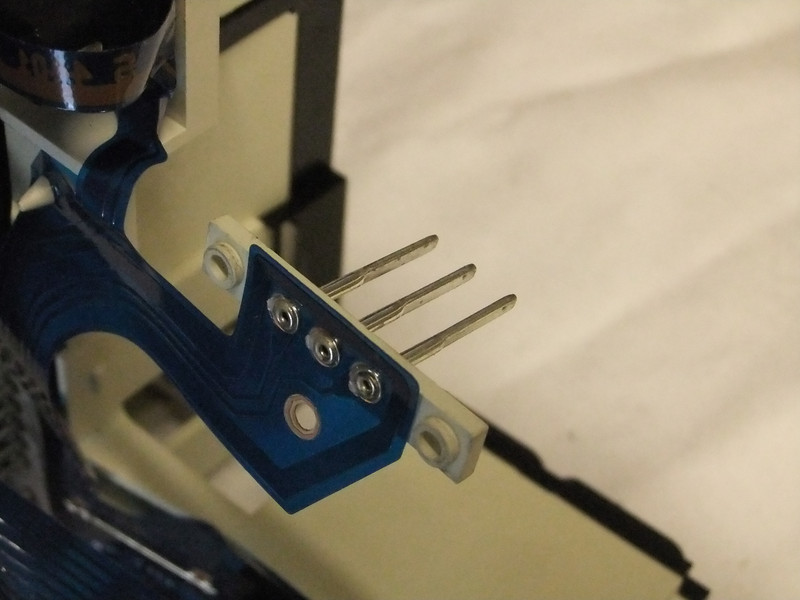

The front brakes were stripped, cleaned, checked and re-assembled:

The screws that hold the calliper halves together were solid with oxidisation, some heat helped free them:

Once again, grotty threads get cleaned as part of the process:

Pistons popped out (my air line) and checked for corrosion (all okay):

All parts cleaned with Wurth brake cleaner:

Before re-assembly using new seals and stainless steel fasteners (with a dob of Alumslip anti-seize):

Another pile of parts for cleaning and re-painting:

More, much more to come.

As you may have worked out, I have nothing better to do with my time and something approaching a fetish for K-Series 'Bricks' (as well as an almost anal approach so I'm told).

The background is this: My nephew, like me, had an R1150GSA but one thing or another has prevented him using it in the way he intended, ie long journeys loaded to the gunwales. I persuaded him that he should sell the GSA and buy something that he can use on the odd occasion that he gets, something inexpensive yet will provide some pride in owning as well being practical.

In short I suggested a K-Series and as he liked the K75S that I'd owned for a short period last year, why not one for himself knowing that I'd enjoy fettling it for him?

Well in December he did a deal on one, a 16,000 mile bike that was in a sad state cosmetically yet mechanically sound. The price was on the low side, accurately reflecting the condition.

It was subsequently delivered to me just after Christmas. My first task was to take it out and make certain that everything worked, plus to evaluate what needed sorting apart from the obvious. My rides showed that it was all fine except that the steering head adjustment was on the tight side of acceptable.

Only once I'd given the bike a wash did realise how poor it was beneath the mud and dirt. In fact, I discovered that someone had taken a can of black paint and squirted it about with gay abandon covering the dirt on the transmission as well as anything else that got in the way such as the air-box and intake tube (among many things).

After some digging, I think that I've worked out that this bike was laid-up in less than than ideal circumstances. Probably a farm or at least a very rural environment where it had been allowed to stand covered in dirt, probably in a puddle of mud judging by the state of the main-stand:

There wasn't one body panel that didn't have damage to the paint. It was always anticipated that some panels would need re-painting but it was a bit of a blow to discover that they all did. One good thing about this is that it makes a colour change an option. If the whole thing needs re-spraying then why not choose a colour that you like? We've chosen a BMW colour that was used for the K75S but one that I don't think was used for UK bikes.

An hour or two saw the panels all removed, stripped of all the fixings and badges and cleaned inside and out:

Another pile saw the parts for refurbishment begin to grow:

It wasn't all plane sailing however. The long screw that passes through the fork brace and holds the two part mudguard together had suffered badly.

I had anticipated this along with the likelihood that the fork leg mudguard retaining screws would also be seized. A couple of days soaking in penetrating oil worked for two screws but the rest were solid.

The fork brace screw began to turn but once the corroded threads reached the captive nut it was game over. Anyone having experienced this will know that access to the screw and the nut is a problem. My first attempt was to clamp the captive screw that was no longer captive (being captive in a plastic housing is probably like being in an open prison);

It failed and I had to drill it out from the rear.

Next, two of the side screws were solid (both on the same side and the side of the bike that seems to have suffered most from the elements, possibly because it was up against a wall with one side a bit better protected). With the forks removed, I set about driling out the screws:

I've had to do this before now and find that leaving the head of the Allen screw in place, it acts as a guide for the drill. Once beyond the depth of the head I cut the head off.

It's always a bit of a leap of faith to drill by hand (not a bench drill) into a steel screw that's housed in soft aluminium. The only saving grace here is that if you end up damaging the ali at least here it's not threaded and nor is the size of the hole crucial. As it is, I use an under-size drill bit then pick out the remains of the screw.

Having done this sort of thing on cars and bikes for many years, I've learnt that my best modus operandi is to clean, polish and refurbish parts as I remove them. That way there's less tendency to get all excited about putting it back together and being tempted to rush things or cut corners. It does make re-assembly quicker and there's a real pleasure to had from taking a component from the shelf that's all sorted when re-assembly begins. It's the nearest I'll ever get to building something new.

So, the forks were stripped, cleaned and the sliders repainted:

The same goes for the smaller parts such as the battery strap screws, the rear mudguard retaining straps and the seat hinge plates:

Removing the paint from the intake tube:

Cleaning the hoses and clips etc;

Done:

I have a pet theory that much of the problems associated with water in the fuel tanks of these bikes is caused by the oxidisation that builds up under the filler and breaks the seal:

It afflicts the seal on the flap too:

It's just a matter of scraping the white crusty muck off, then a dob of rubber treatment helps the seals remain flexible:

The matt finish always discolours from polish. A wipe with acetone or even brake cleaner is enough to return it to as new:

The tight steering was explained by an over-tightened adjuster. The bearings were just starting to show signs of brinelling. They're too cheap to ignore so it's off with them:

The bare aluminium fork clamps had suffered the usual oxidisation and the screws the usual steel into ali, add moisture and you get cement issues. The threads were cleaned with a tap:

Then the fork clamp given a quick spin with an emery wheel:

And finally the whole thing gets a quick buff-up with steel wool and Solvol metal polish:

The upper clamp gets the same treatment, before:

After:

The box of cleaned or refurbished parts grows:

More washing, scrubbing and polishing done:

The radiator was flushed through, cleaned and the fan tested:

The front brakes were stripped, cleaned, checked and re-assembled:

The screws that hold the calliper halves together were solid with oxidisation, some heat helped free them:

Once again, grotty threads get cleaned as part of the process:

Pistons popped out (my air line) and checked for corrosion (all okay):

All parts cleaned with Wurth brake cleaner:

Before re-assembly using new seals and stainless steel fasteners (with a dob of Alumslip anti-seize):

Another pile of parts for cleaning and re-painting:

More, much more to come.