1

Putting your gearbox back together Thu Jun 28, 2012 3:29 pm

Putting your gearbox back together Thu Jun 28, 2012 3:29 pm

twincarb

Life time member

I have just put my gearbox back together having had the casing sent to be cleaned.... Not impressed with how "clean" it came back, but its a lot better than before...

The pictures and steps below are the method I used while folowing the Hanynes manual... There photo's are black and white so lack some detail.

First off I am starting with an empty shell with all of the Seals removed, a replacement seal kit is avalible from Motobin's etc however they don't come with instructions so I will show where some of the not so obvious one's fit as we go along.

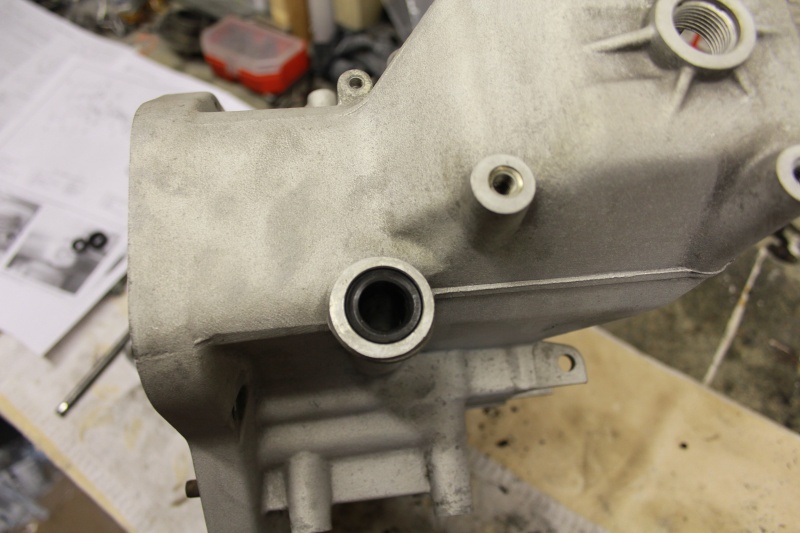

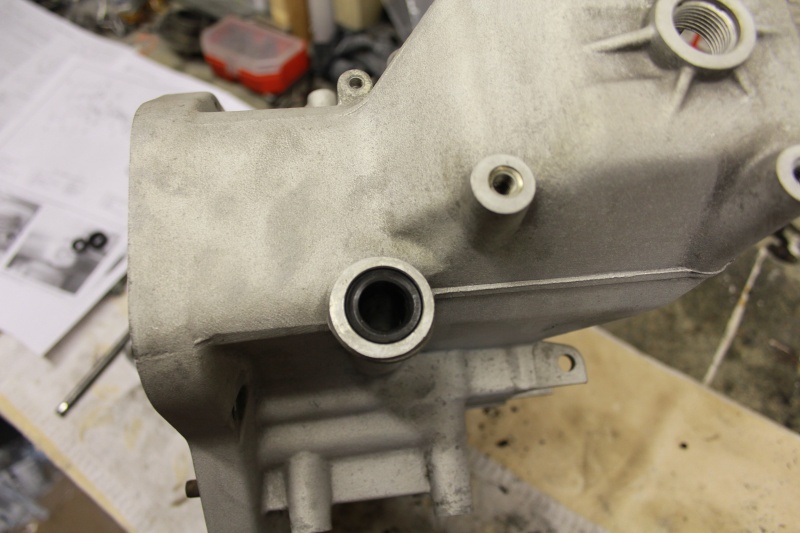

The first seal fits here on the side, which is where the gear change lever fits.

Once you have fitted the replacment oil seal you need to connect the pedal onto the shaft, align it into the same position as it came off. I was lucky with mine that it was very easy to remember, I took a photo before I removed it so wouldnt forget. You can also mark both the parts where they fit together.

Next you put these parts back into place. Make sure you remember the washer/shim that fits between the spring and the case.

Also the cross memeber needs fitting at the same time! this is held in place by the 2 E clips that you removed during dissassembly... Loctite is needed on the allen screw to ensure it doesn't work loose. Some people have found this has happened over time.

Next you insert the bar from the oil pressure relief cover opening, ensurnig all parts mate together in a natural manner.

Next is the Input shaft, note you need to lubricate the bearings before you put it into place, esp if you have changed the bearing's also if you did change them make sure they are free from grease.

There is an oil seal here which is for the gear position selector.

This is the smallest of the oil seal's you can just see that it is in the end ... now you can seat the input shaft in place...

Next to go in are the Layshaft and Output shafts, most people are lucky and only need to wiggle them into place, you may need to give them a tap alternatly and will find that they drive naturally into place.

You do remember where the selector forks go don't you.... if not refer to the Haynes diagram Chapter 3 fig 3.3 I have labled them below with the part numbers in the diagram.

The image below shows how they interlock understanding this will help with knowing where each part fits in.

Next put the selector forks into position on the shafts... you will notice that the Roller that is on all 3 selector forks is in place, a small dob of grease will hold them in place while you make a coffee or grab a beer from the fridge...

I now put the selector fork shafts into place, don't recess them into there home's yet mind as thats coming up in a moment...

The selector drum assembly can now be put into place, rotate it so it is aligned as shown. this is so the gearbox is placed into neutral... It also means that the selector forks all drop into place... you may find that there is a slight lifting of the gears to get them into position mind...

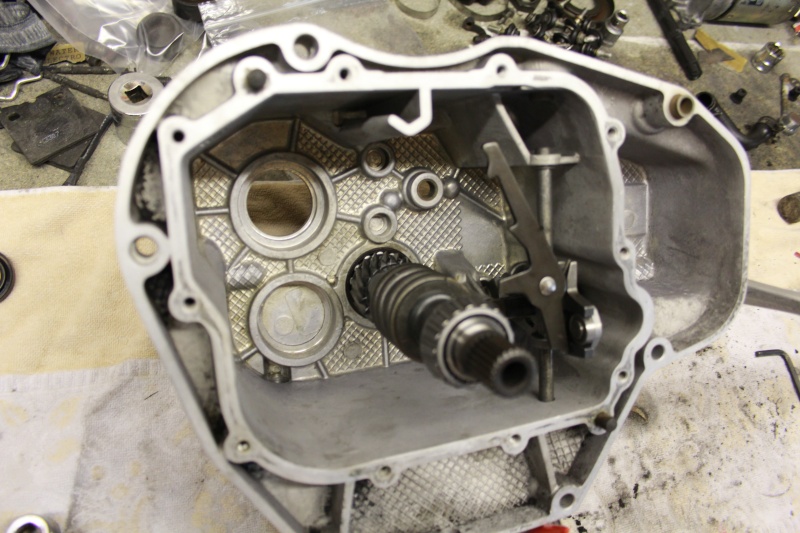

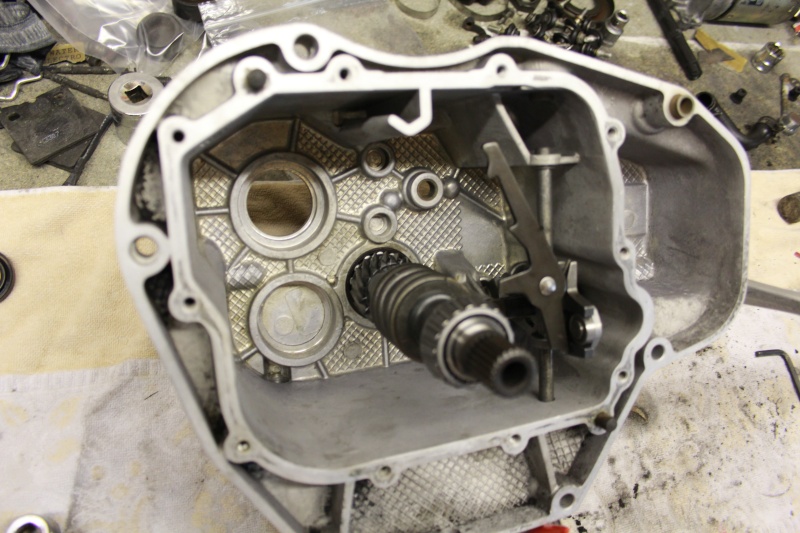

This is with everything dropped into place and everything is seated just where it should be...

Next up those shims that you carefully paid attention to where they came from need to go into the "lid" hold them in place with a spot of grease, this will hold them in place while the cover in manipulated as well. Now would also be a good time to apply your Sealant.... however.... procede to the next step as it will allow you to put the case back on!

There is a blanking plug that needs to be popped out... this will allow you to hold back the sprug arm... I used a handy bit of metal that was close to me....

With the gasket cement in place place the lid back on, ensuring all components appear in the right place....

The final step is to put the ball bearing follwoed by the spring back into place and tighten the bolt up to the required toque....

I may have ommitted some information and don't come after me if it all go's wrong! It worked for me....

The pictures and steps below are the method I used while folowing the Hanynes manual... There photo's are black and white so lack some detail.

First off I am starting with an empty shell with all of the Seals removed, a replacement seal kit is avalible from Motobin's etc however they don't come with instructions so I will show where some of the not so obvious one's fit as we go along.

The first seal fits here on the side, which is where the gear change lever fits.

Once you have fitted the replacment oil seal you need to connect the pedal onto the shaft, align it into the same position as it came off. I was lucky with mine that it was very easy to remember, I took a photo before I removed it so wouldnt forget. You can also mark both the parts where they fit together.

Next you put these parts back into place. Make sure you remember the washer/shim that fits between the spring and the case.

Also the cross memeber needs fitting at the same time! this is held in place by the 2 E clips that you removed during dissassembly... Loctite is needed on the allen screw to ensure it doesn't work loose. Some people have found this has happened over time.

Next you insert the bar from the oil pressure relief cover opening, ensurnig all parts mate together in a natural manner.

Next is the Input shaft, note you need to lubricate the bearings before you put it into place, esp if you have changed the bearing's also if you did change them make sure they are free from grease.

There is an oil seal here which is for the gear position selector.

This is the smallest of the oil seal's you can just see that it is in the end ... now you can seat the input shaft in place...

Next to go in are the Layshaft and Output shafts, most people are lucky and only need to wiggle them into place, you may need to give them a tap alternatly and will find that they drive naturally into place.

You do remember where the selector forks go don't you.... if not refer to the Haynes diagram Chapter 3 fig 3.3 I have labled them below with the part numbers in the diagram.

The image below shows how they interlock understanding this will help with knowing where each part fits in.

Next put the selector forks into position on the shafts... you will notice that the Roller that is on all 3 selector forks is in place, a small dob of grease will hold them in place while you make a coffee or grab a beer from the fridge...

I now put the selector fork shafts into place, don't recess them into there home's yet mind as thats coming up in a moment...

The selector drum assembly can now be put into place, rotate it so it is aligned as shown. this is so the gearbox is placed into neutral... It also means that the selector forks all drop into place... you may find that there is a slight lifting of the gears to get them into position mind...

This is with everything dropped into place and everything is seated just where it should be...

Next up those shims that you carefully paid attention to where they came from need to go into the "lid" hold them in place with a spot of grease, this will hold them in place while the cover in manipulated as well. Now would also be a good time to apply your Sealant.... however.... procede to the next step as it will allow you to put the case back on!

There is a blanking plug that needs to be popped out... this will allow you to hold back the sprug arm... I used a handy bit of metal that was close to me....

With the gasket cement in place place the lid back on, ensuring all components appear in the right place....

The final step is to put the ball bearing follwoed by the spring back into place and tighten the bolt up to the required toque....

I may have ommitted some information and don't come after me if it all go's wrong! It worked for me....

__________________________________________________

BMW K100LT 1988

Yamaha Thundercat

Triumph Spitfire (not a bike but hell it's British chaps)