1

Analysis and modification of stock and retrorides suspension Sat Aug 08, 2020 7:37 pm

Analysis and modification of stock and retrorides suspension Sat Aug 08, 2020 7:37 pm

BrickedOut

active member

Where to begin…

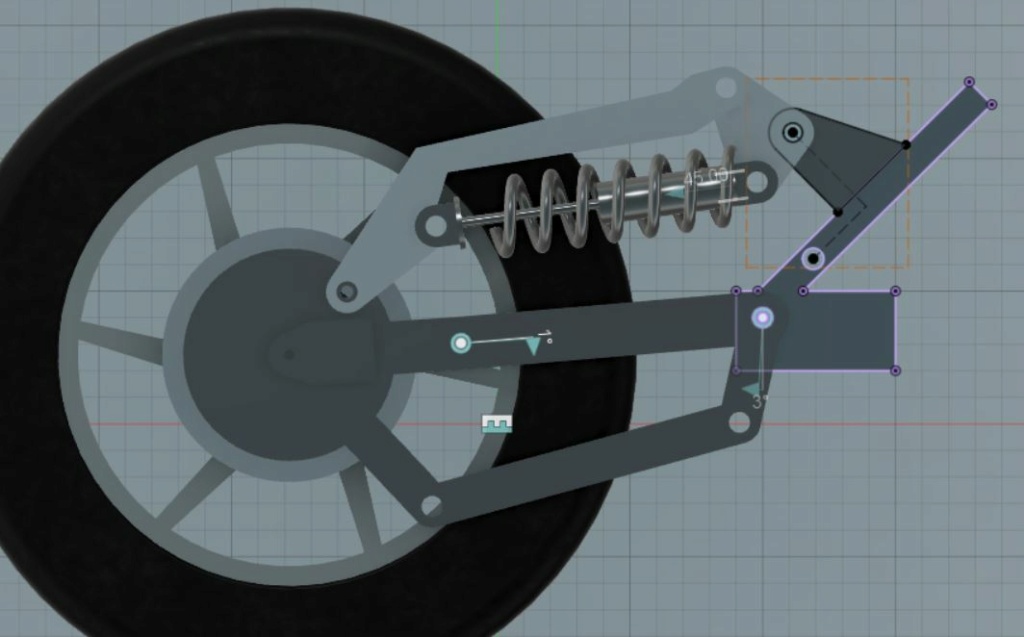

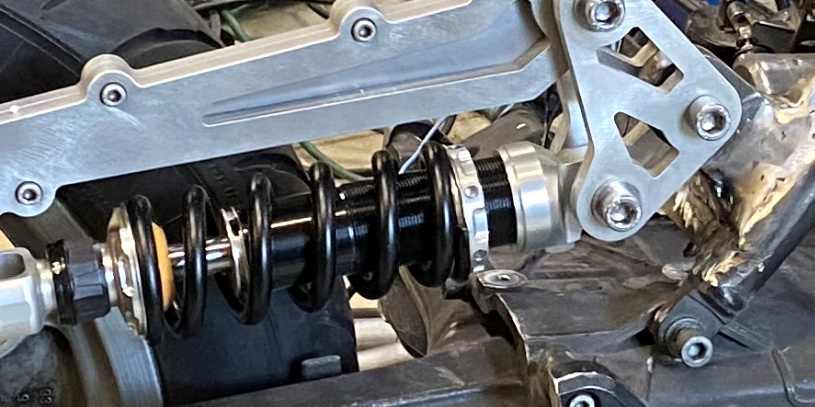

I decided to use the retrorides suspension on my k1100 build and just got it in a couple weeks ago. Great aesthetics if you ask me. Opens up the back end and allows for a seat with a nice straight line parallel to the tank. That said, after cutting my frame and placing the parts loosely where they’re supposed to go, I noticed a pretty big issue. Despite all of the sites that sell them saying they work for K1100’s in their descriptions, I found a single line in the booklet the designer wrote that states the suspension is only meant for monolever rear ends. And of course I have the paralever on my K1100. I noticed this when the measurements weren’t matching up the way they should have. Turns out the swingarms are actually slightly different lengths, and of course the paralever swingarm has an extra joint in the middle of it. I searched around and found a few other pictures online of K1100’s with the modification but I doubt they went through the trouble of remodeling the whole thing to get the correct leverage ratio. So I decided to model up the suspension based on the original CAD files and my own measurements on the bike to adjust for the different geometry and get a corrected mounting position with a decent leverage ratio for my weight. Skip to the end for my summary if you don’t want to read through the technical details.

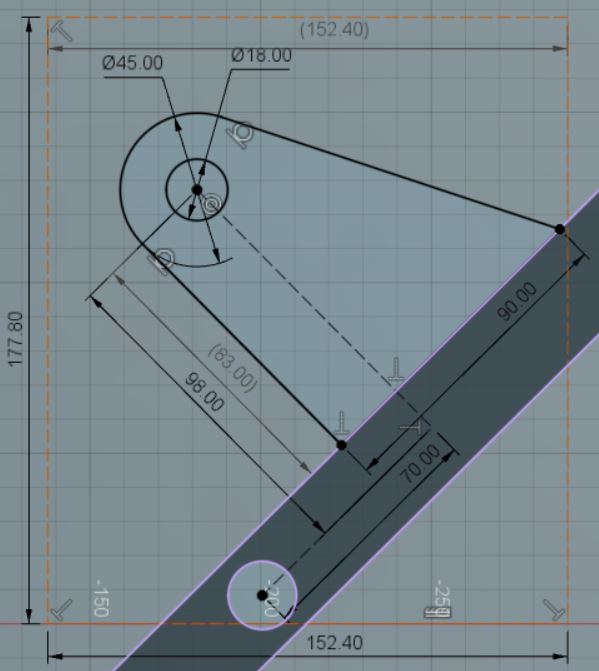

I modeled the monolever suspension first in order to verify the original design and compare. The dimensions did, in fact, work out correctly for the monolever which reaffirmed to me that the paralever rear end is a different length.

Getting into it, the leverage ratio was an average of about 2.15. Stock LR is about 1.28 on average (calculated based on geometry at full extension). Stock spring rate is 5.5 kg/mm and I believe the typical for progressive shocks is 5 - 6 kg/mm. Using the equation Stock SR/Stock LR = New SR/New LR where SR is spring rate and LR is leverage ratio in order to determine an equivalent new spring rate, we get a new required spring rate of 7.7 kg/mm. The suggested springs for the kit (YSS MA366-352TR-52) have a spring rate of 10 kg/mm which should suffice if you’re fairly heavy and want an extra safety margin, but considering this kit is intended to accommodate only a single rider, it makes more sense to go with a softer suspension than stock which means the leverage ratio needs to be higher.

Another glaring issue with the design is the regressive leverage ratio. Look anywhere for a similar design on a production motorcycle or bike and you won’t find it because it results in a regressive leverage ratio. The whole point of having a rocker and linkage setup is to be able to modify the leverage ratio curve to something more desirable than can be achieved with the traditional single pivot design. Typically a progressive (decreasing through wheel travel) leverage ratio is best. This results in a ride that is soft in the beginning of its travel and gradually gets harder. This makes small bumps softer while helping to limit travel for larger bumps. With a regressive curve the opposite happens. Small bumps are hard and the suspension gets softer when hitting large bumps which risks bottoming out on the suspension. You can see this in the leverage ratio chart. I suspect this is the reason why a stiffer spring was chosen. I did my best to change things so that it’s a flat curve in my own design. It can be hard to find information on the leverage ratio curves of other motorcycles but typically sport bikes tend to have fairly flat curves and cruisers are more progressive. You can see in the same chart that the stock leverage ratio is progressive, although just slightly. Using a progressive spring with the stock setup ends up making the suspension quite progressive. This is one reason why I was so surprised that the retrorides suspension is regressive and doesn’t use a progressive spring to compensate.

I decided to use the retrorides suspension on my k1100 build and just got it in a couple weeks ago. Great aesthetics if you ask me. Opens up the back end and allows for a seat with a nice straight line parallel to the tank. That said, after cutting my frame and placing the parts loosely where they’re supposed to go, I noticed a pretty big issue. Despite all of the sites that sell them saying they work for K1100’s in their descriptions, I found a single line in the booklet the designer wrote that states the suspension is only meant for monolever rear ends. And of course I have the paralever on my K1100. I noticed this when the measurements weren’t matching up the way they should have. Turns out the swingarms are actually slightly different lengths, and of course the paralever swingarm has an extra joint in the middle of it. I searched around and found a few other pictures online of K1100’s with the modification but I doubt they went through the trouble of remodeling the whole thing to get the correct leverage ratio. So I decided to model up the suspension based on the original CAD files and my own measurements on the bike to adjust for the different geometry and get a corrected mounting position with a decent leverage ratio for my weight. Skip to the end for my summary if you don’t want to read through the technical details.

I modeled the monolever suspension first in order to verify the original design and compare. The dimensions did, in fact, work out correctly for the monolever which reaffirmed to me that the paralever rear end is a different length.

Getting into it, the leverage ratio was an average of about 2.15. Stock LR is about 1.28 on average (calculated based on geometry at full extension). Stock spring rate is 5.5 kg/mm and I believe the typical for progressive shocks is 5 - 6 kg/mm. Using the equation Stock SR/Stock LR = New SR/New LR where SR is spring rate and LR is leverage ratio in order to determine an equivalent new spring rate, we get a new required spring rate of 7.7 kg/mm. The suggested springs for the kit (YSS MA366-352TR-52) have a spring rate of 10 kg/mm which should suffice if you’re fairly heavy and want an extra safety margin, but considering this kit is intended to accommodate only a single rider, it makes more sense to go with a softer suspension than stock which means the leverage ratio needs to be higher.

Another glaring issue with the design is the regressive leverage ratio. Look anywhere for a similar design on a production motorcycle or bike and you won’t find it because it results in a regressive leverage ratio. The whole point of having a rocker and linkage setup is to be able to modify the leverage ratio curve to something more desirable than can be achieved with the traditional single pivot design. Typically a progressive (decreasing through wheel travel) leverage ratio is best. This results in a ride that is soft in the beginning of its travel and gradually gets harder. This makes small bumps softer while helping to limit travel for larger bumps. With a regressive curve the opposite happens. Small bumps are hard and the suspension gets softer when hitting large bumps which risks bottoming out on the suspension. You can see this in the leverage ratio chart. I suspect this is the reason why a stiffer spring was chosen. I did my best to change things so that it’s a flat curve in my own design. It can be hard to find information on the leverage ratio curves of other motorcycles but typically sport bikes tend to have fairly flat curves and cruisers are more progressive. You can see in the same chart that the stock leverage ratio is progressive, although just slightly. Using a progressive spring with the stock setup ends up making the suspension quite progressive. This is one reason why I was so surprised that the retrorides suspension is regressive and doesn’t use a progressive spring to compensate.

Leverage ratio comparison. Don’t forget the stock ratio is lower than the rest because a softer spring rate is used.