1

Swingarm Disassembly & Proper lubrication Fri Apr 27, 2018 4:37 am

Swingarm Disassembly & Proper lubrication Fri Apr 27, 2018 4:37 am

George_Pap

Silver member

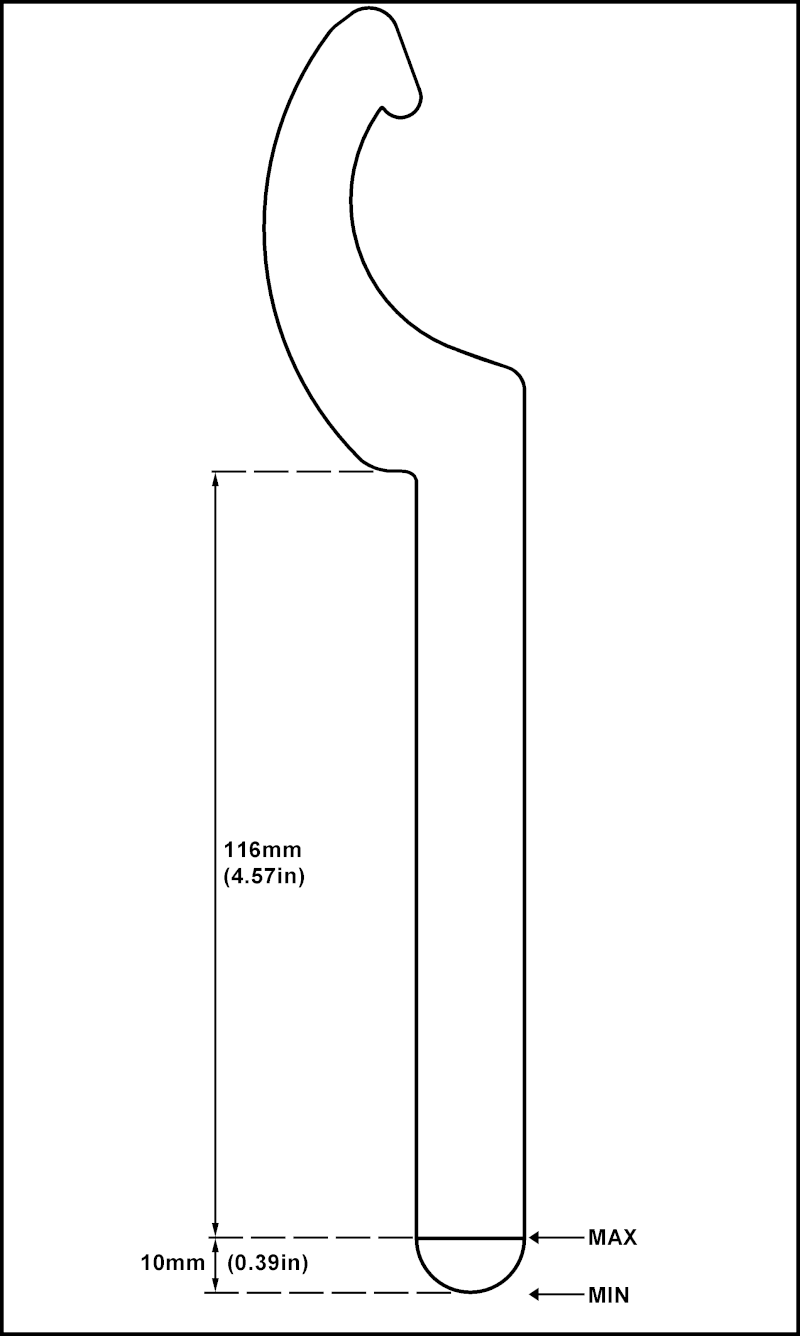

Hey community. Ι need to remove the rear swingarm on my early 1985 K100RT in order to check and replace my non functioning Gpi Sensor

Bike has already removed the rear fender-plate holder so i need to know the correct steps to do the disassembly.

I m describing so if something's wrong please advise:

1. Remove Rear brake caliper

2. Remove Speed sensor

3. Remove wheel ( i' m also replacing Rotor with a Brembo series Oro and proper calipers )

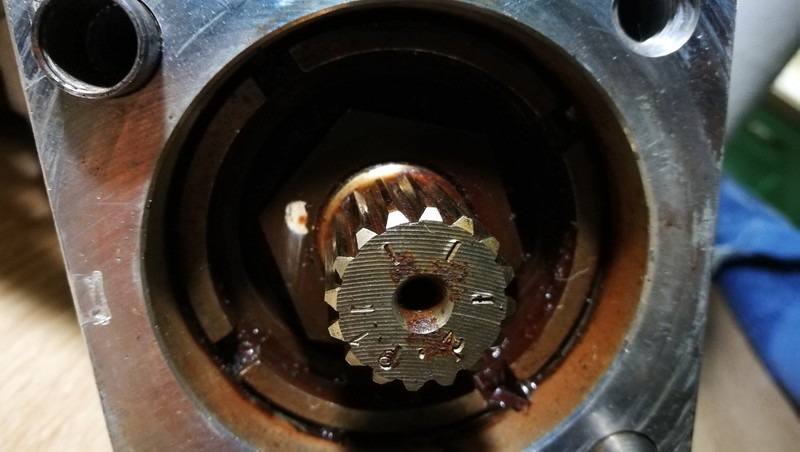

4. Remove final drive ( 4 allen bolts)?

Do i need to bleed the lubricant of the final drive shaft before that?

4. Remove left footpeg baseplate and the big hex nut and corresponding allen bolt

5. Remove the round plate from right side ( three allen + one in the center )

6. Detach Clutch cable

7. Pull back the swingarm.

Lubricants needed:

1. Lithium White Grease for the spline

2. Lubricant (Type?) for the rear drive shaft

3. brake fluid for bleeding due to calipers replacement.

Anything missing? Its my first time and due to weekend i need to be sure that i m not missing anything

Thank you .

Bike has already removed the rear fender-plate holder so i need to know the correct steps to do the disassembly.

I m describing so if something's wrong please advise:

1. Remove Rear brake caliper

2. Remove Speed sensor

3. Remove wheel ( i' m also replacing Rotor with a Brembo series Oro and proper calipers )

4. Remove final drive ( 4 allen bolts)?

Do i need to bleed the lubricant of the final drive shaft before that?

4. Remove left footpeg baseplate and the big hex nut and corresponding allen bolt

5. Remove the round plate from right side ( three allen + one in the center )

6. Detach Clutch cable

7. Pull back the swingarm.

Lubricants needed:

1. Lithium White Grease for the spline

2. Lubricant (Type?) for the rear drive shaft

3. brake fluid for bleeding due to calipers replacement.

Anything missing? Its my first time and due to weekend i need to be sure that i m not missing anything

Thank you .

__________________________________________________

K100RT (Early 1985 -nonABS)