1

Oil leak from oil pressure sensor wire hole Tue Jun 17, 2008 1:29 pm

Oil leak from oil pressure sensor wire hole Tue Jun 17, 2008 1:29 pm

scottiesharpe

Silver member

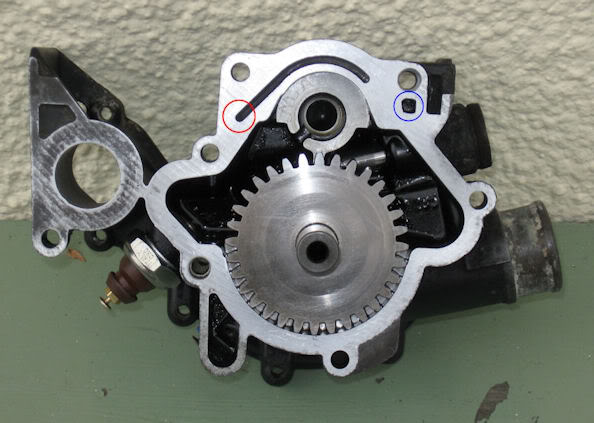

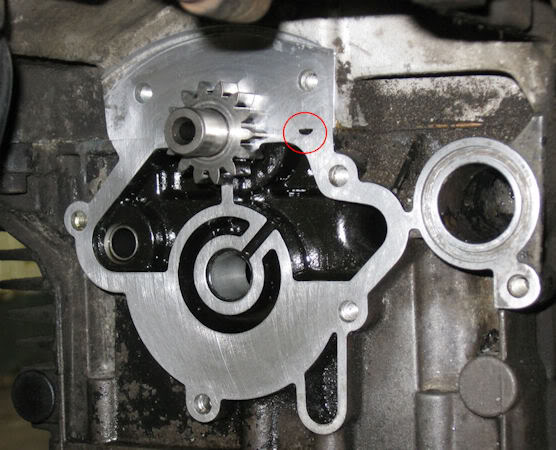

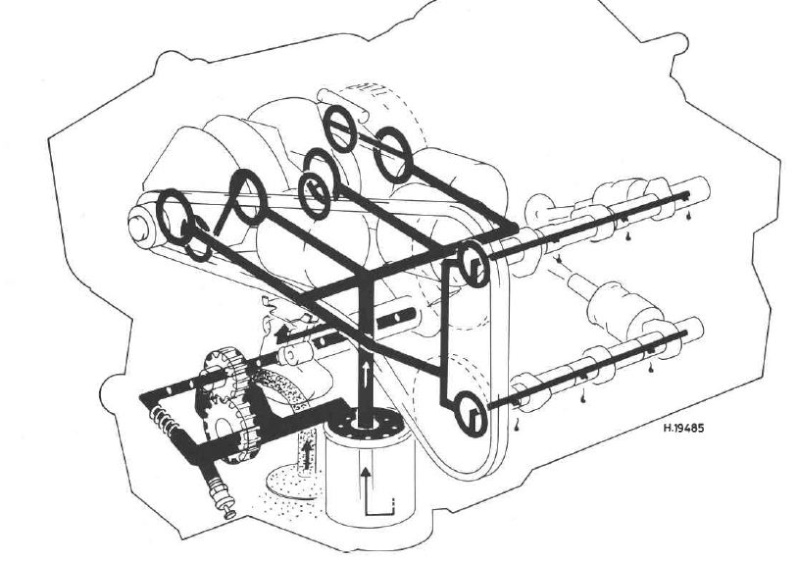

What was once a "weep" has now turned into a "drip" from the oil pressure sensor wire access hole on the water pump housing. I've heard from my parts sources that the rebuild kit for the water pump is NLA and the new unit is a one peice replacement. I'm headed over to the BMW dealer now to seek pricing and possibly just buy the replacement as I am off today from work but have to get rolling by tomorrow and I don't like the idea of getting oil all over my rear tire. Will keep you posted on what transpires...

Scottie

87 K100RT

San Jose CA

Scottie

87 K100RT

San Jose CA

1986 k75, 1985 K100rt,

1986 k75, 1985 K100rt,

).

).