1

LE Jetronic injection vs aftermarket ECU and sensors Thu Feb 07, 2013 4:40 pm

LE Jetronic injection vs aftermarket ECU and sensors Thu Feb 07, 2013 4:40 pm

Halo

Life time member

So this has been brought forward from TWB pride and Joy thread as it became technical discussion on LE Jetronic and pretty much started my investigations with this comment.

Which made me do 8 hours of research so far (s loads more to come ) but after my initial look this was my opinion so far

So I have started my research on both the LE injection (E is for open loop non lambda sensor type, that is non oxygen sensor with close loop response type). Initial thoughts as follows

LE injection system is an antiquated (but lovely guys I like these old girls remember) way to run a fuel injection system that relies on operating with a predetermined (open loop) fuel map instead of closed loop feedback controlled fuel injection that varies the fuel injector output according to real time data, whilst the closed loop system is useful for fuel emissions( dont really care) it is also advantages for fuel injection efficiency.

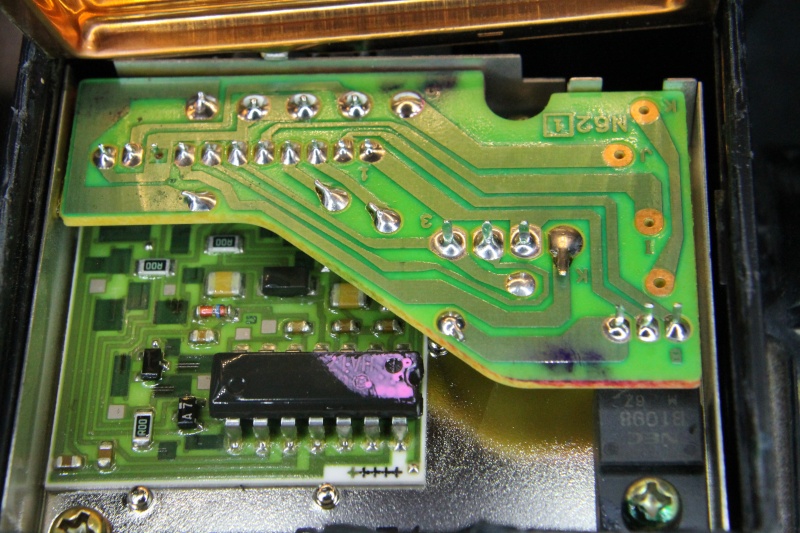

The FI(fuel injection) module in our girls isn't even microprocessor controlled, purely a analog (hardware solution) you purely follow the rpm signal through whilst it is divided down and condition (mainly by the rpm & afm signals) but post conditioned via capacitive & resistive slew rates fed via temp sensor et, then fed into a logic gate to clean up the signal and out to the injectors.

You can modify the afm preload and it is true that this will adjust (enrich) the outcome for performance at the exspense of fuel efficiency and emmisions but you can't measure real time and adjust accordingly through the rev range. Resistor changes can be made to the rpm rev limit (alot on this in forums alfas, volvo etc) and other points that will change max dwell etc and these can be changed and tested as at the end of the day you are just following a waveform with the scope to the injectors. Funny really you can think of the resistor changes as constant parameters in software for a micro controller, variable only at the design( variants for different car types) and manufacturing stage and burnt into OTP (one time programable) micro controllers.

However we all know how much difference a performance chip upgrade to a modern car can improve its power(it's just remapped).

What about tunning for a different exhaust system or modification like K1100 TB's etc or even better?.

The equation for lambda 14.7:1 is for max emmisions efficienty not power therefore a narrow band oxygen sensor is no good and a wide band sensor will be purchased so I can check O2 levels at different AFR's

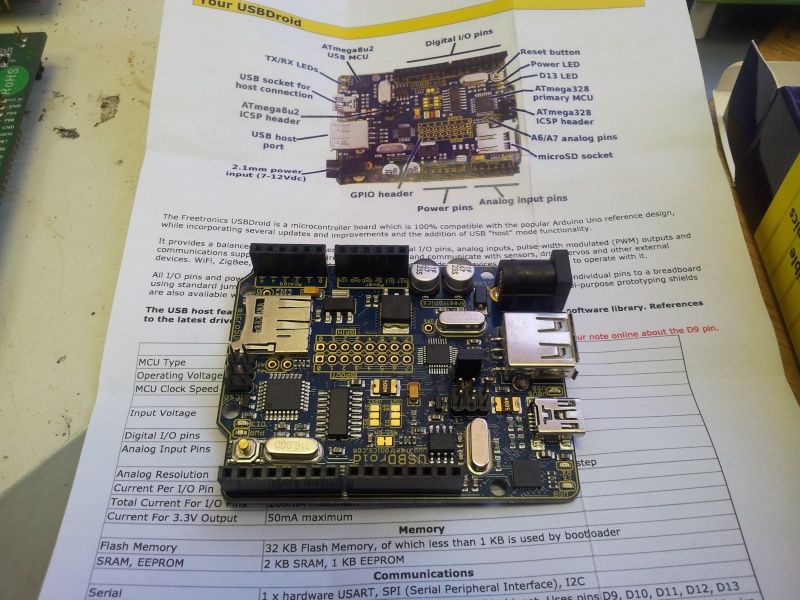

So the go is a mega squirt 3 with the expander card for sequential injection with the version three main board, this will give me bluetooth to my galaxy note for tuning realtime on the road all up around $600 for the kit form (with $200 O2 sensor included)

The original ignition module will be used for logic level ignition sequencer driven from the megasquirt.

Not bad value when they offer the MS3 premade in a IP69 rated case (dont care for me) for around $1200 without the lambda sensor

Wow it is facinating reading about fuel injection systems

Halo

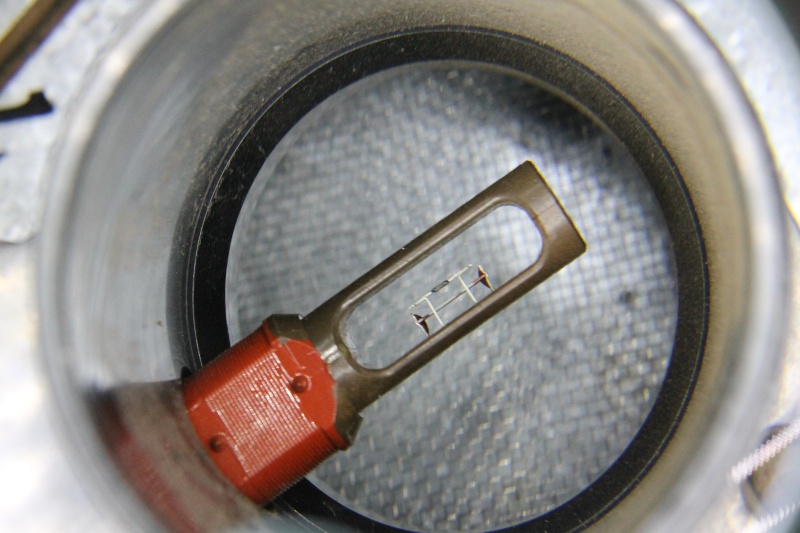

Themason wrote:There is nothing to be gained from a Megasquirt injection system except the opportunity to get it very wrong. Whether or not you chose to go with Megasquirt or learn the black arts behind Bosch L-Jetronic, you will still have to learn the basics of fuel injection and the details of a particular system. Take it from me, L-Jet has no real shortcomings and is easily tunable with hand tools, once you understand what you are doing inside that black plastic cover over the potentiometer (and learn how to pry it off gently without damaging it).

There are automotive websites that explain what goes on inside an air flow meter and how to modify them. A one click reduction in spring pre-load on the vane changes throttle response a lot. Two clicks on some bikes is too much. You will have to learn how to adjust the potentiometer in suit with adjustments to spring pre-load on the vane. In reality it is easier than trying to suss out an AFR table on something like a Megasquirt. L-Jet gives you a dead flat AFR across the rev range if you keep the TPS installed. If you have spent any time dyno tuning an Alfa-N system you know this is not so easy to achieve on other systems.

L-Jet and the stock injectors can deliver more fuel than the engine can use, so don't fool yourself into thinking you can get more power out of some other form of fuel injection.

Which made me do 8 hours of research so far (s loads more to come ) but after my initial look this was my opinion so far

So I have started my research on both the LE injection (E is for open loop non lambda sensor type, that is non oxygen sensor with close loop response type). Initial thoughts as follows

LE injection system is an antiquated (but lovely guys I like these old girls remember) way to run a fuel injection system that relies on operating with a predetermined (open loop) fuel map instead of closed loop feedback controlled fuel injection that varies the fuel injector output according to real time data, whilst the closed loop system is useful for fuel emissions( dont really care) it is also advantages for fuel injection efficiency.

The FI(fuel injection) module in our girls isn't even microprocessor controlled, purely a analog (hardware solution) you purely follow the rpm signal through whilst it is divided down and condition (mainly by the rpm & afm signals) but post conditioned via capacitive & resistive slew rates fed via temp sensor et, then fed into a logic gate to clean up the signal and out to the injectors.

You can modify the afm preload and it is true that this will adjust (enrich) the outcome for performance at the exspense of fuel efficiency and emmisions but you can't measure real time and adjust accordingly through the rev range. Resistor changes can be made to the rpm rev limit (alot on this in forums alfas, volvo etc) and other points that will change max dwell etc and these can be changed and tested as at the end of the day you are just following a waveform with the scope to the injectors. Funny really you can think of the resistor changes as constant parameters in software for a micro controller, variable only at the design( variants for different car types) and manufacturing stage and burnt into OTP (one time programable) micro controllers.

However we all know how much difference a performance chip upgrade to a modern car can improve its power(it's just remapped).

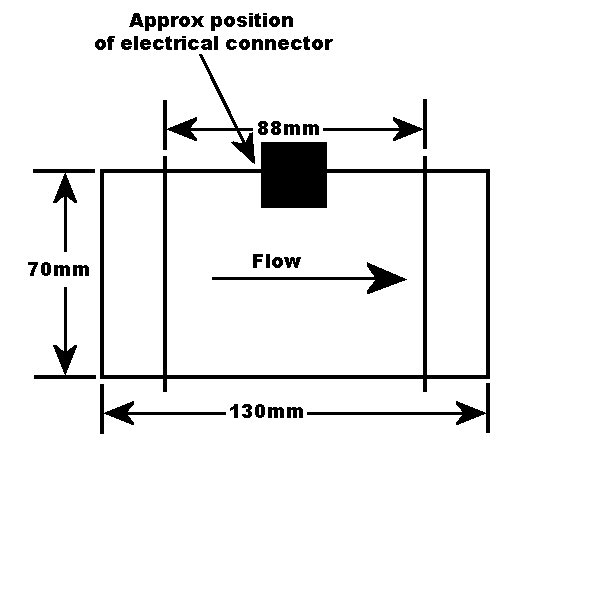

What about tunning for a different exhaust system or modification like K1100 TB's etc or even better?.

The equation for lambda 14.7:1 is for max emmisions efficienty not power therefore a narrow band oxygen sensor is no good and a wide band sensor will be purchased so I can check O2 levels at different AFR's

So the go is a mega squirt 3 with the expander card for sequential injection with the version three main board, this will give me bluetooth to my galaxy note for tuning realtime on the road all up around $600 for the kit form (with $200 O2 sensor included)

The original ignition module will be used for logic level ignition sequencer driven from the megasquirt.

Not bad value when they offer the MS3 premade in a IP69 rated case (dont care for me) for around $1200 without the lambda sensor

Wow it is facinating reading about fuel injection systems

Halo

__________________________________________________

84 K100RS 0014803

93 FZR1000 EXUP